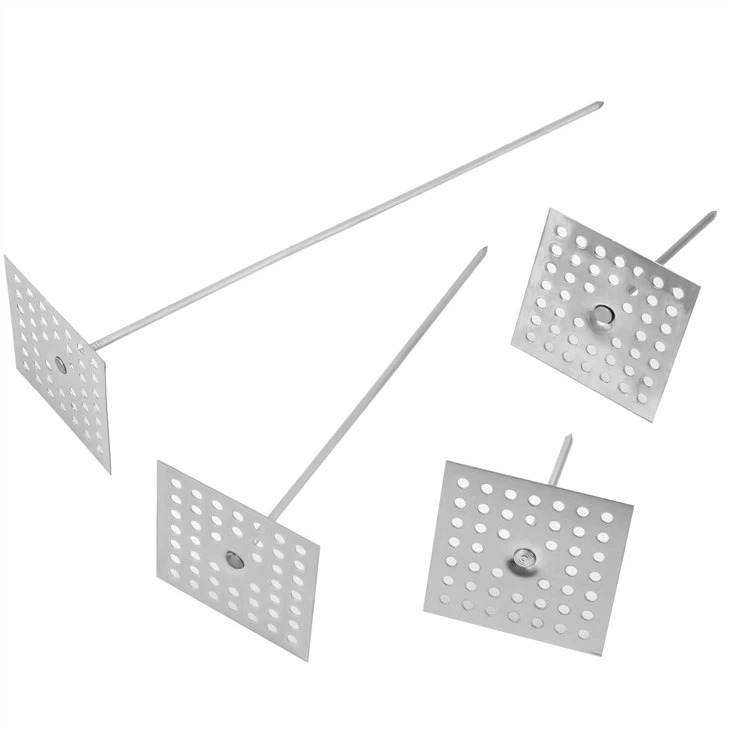

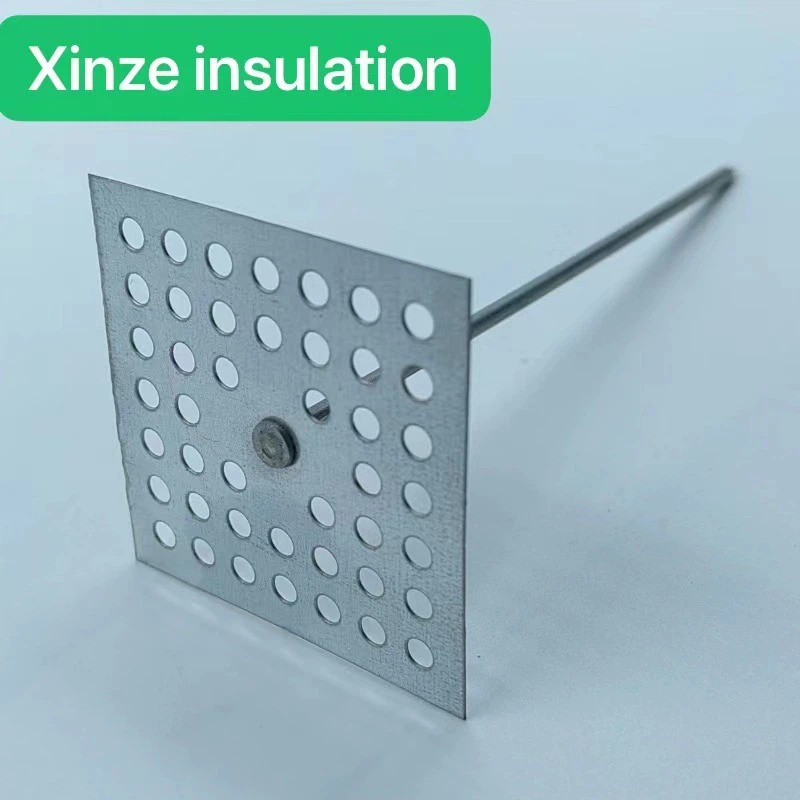

Rock Wool Insulation Perforated Base Insulation Pins

Rock Wool Insulation Perforated Base Insulation Pins are a specialized fastening solution specifical

Contact

Product Detail

Rock Wool Insulation Perforated Base Insulation Pins are a specialized fastening solution specifically designed to meet the unique requirements of rock wool insulation installations. These pins play a crucial role in ensuring the stability and effectiveness of the insulation system.

The combination of rock wool insulation and perforated base insulation pins offers several significant advantages. Rock wool is known for its excellent thermal and acoustic insulation properties, as well as its fire resistance. When paired with the perforated base insulation pins, it creates a secure and reliable insulation setup.

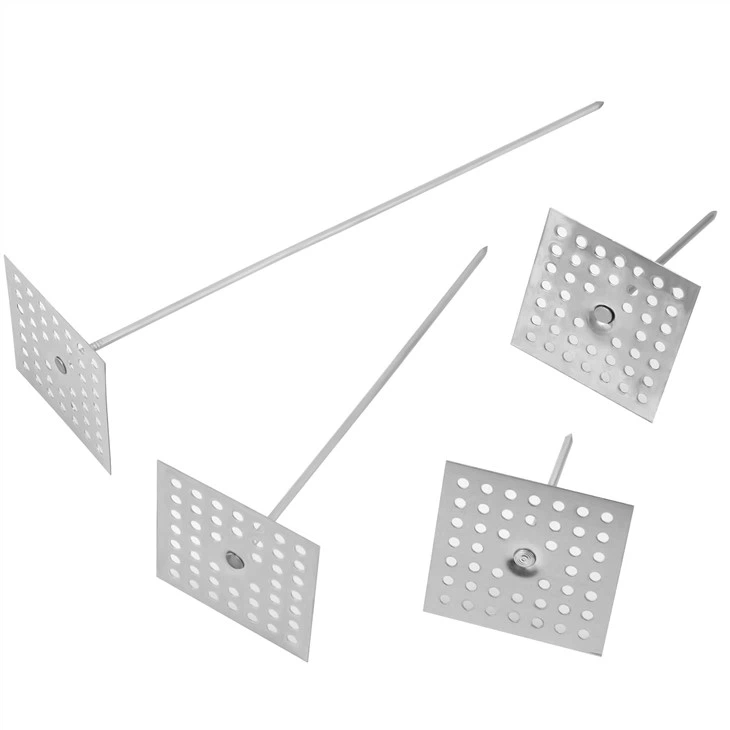

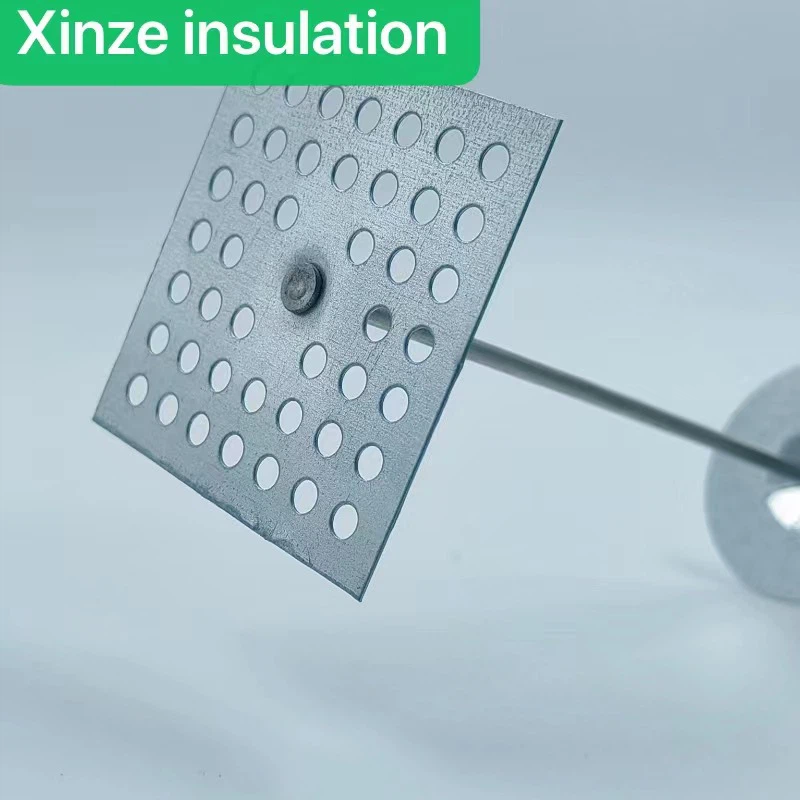

The perforated base of these pins is a key feature that enhances the performance of the insulation system. The perforations allow for improved air circulation within the insulation layer. This is vital as it helps prevent the accumulation of moisture, which can compromise the insulation's effectiveness and lead to mold growth. Good air movement through the perforations also helps maintain the rock wool's insulation properties over time.

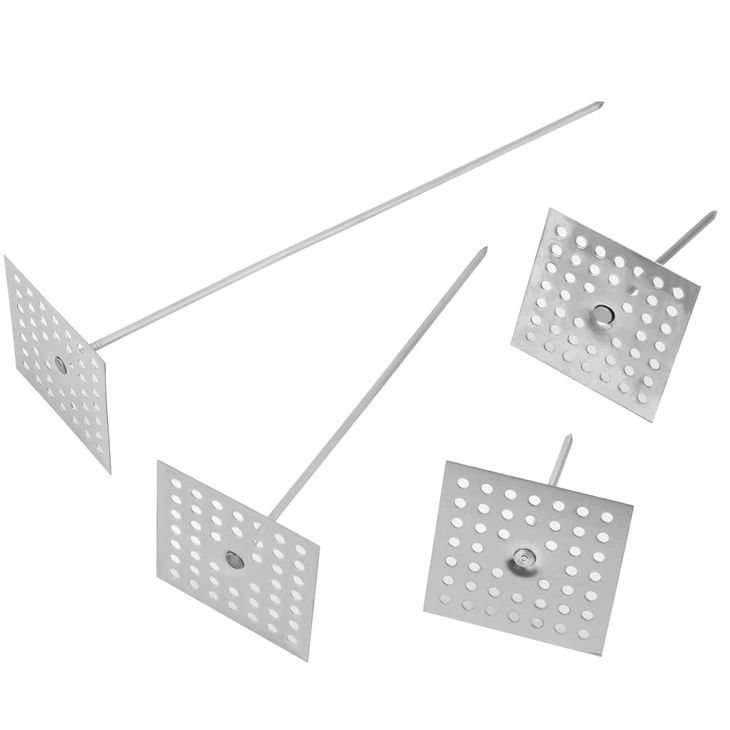

In addition, the perforated base helps distribute the weight of the insulation more evenly. This reduces the stress on individual points and minimizes the risk of the insulation sagging or shifting. It ensures a consistent and uniform insulation layer, maximizing the thermal and acoustic benefits.

For example, in industrial buildings where noise reduction and energy efficiency are critical, the Rock Wool Insulation Perforated Base Insulation Pins can be used to install rock wool insulation in walls and ceilings. The pins provide a secure hold, and the perforated base helps maintain the insulation's performance in challenging environments.

In residential construction, these pins can be employed in attic insulation to improve the home's energy efficiency. The rock wool insulation, along with the perforated base pins, helps create a comfortable living environment and reduces heating and cooling costs.

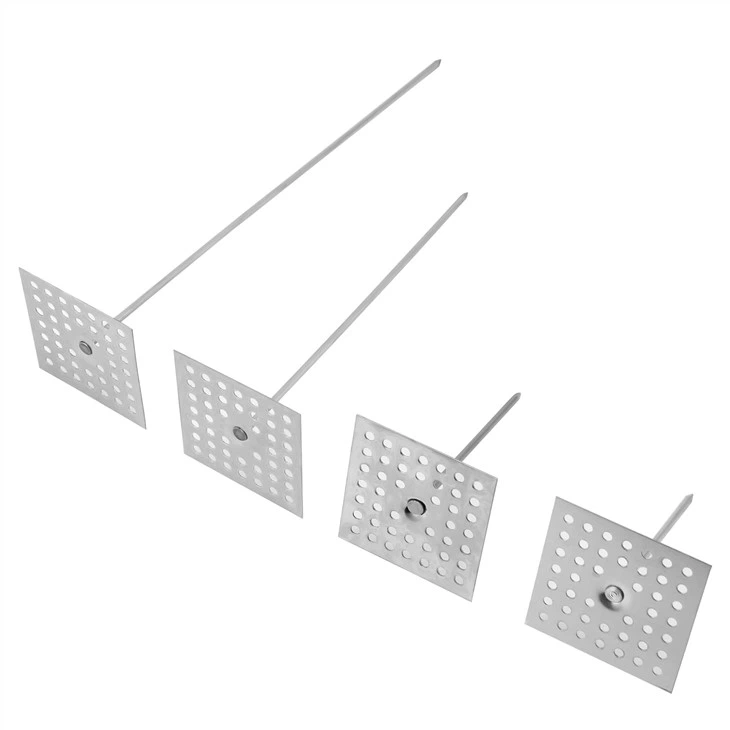

The material used to manufacture these pins is typically chosen for its durability and compatibility with rock wool insulation. It may be made of stainless steel or other corrosion-resistant materials to ensure long-term performance.

Furthermore, the design of the pins takes into account the specific characteristics of rock wool, allowing for easy installation without damaging the insulation material.

In conclusion, the Rock Wool Insulation Perforated Base Insulation Pins offer a comprehensive and effective solution for achieving high-quality rock wool insulation installations. Their combination of functionality, durability, and compatibility makes them an ideal choice for a wide range of construction projects.