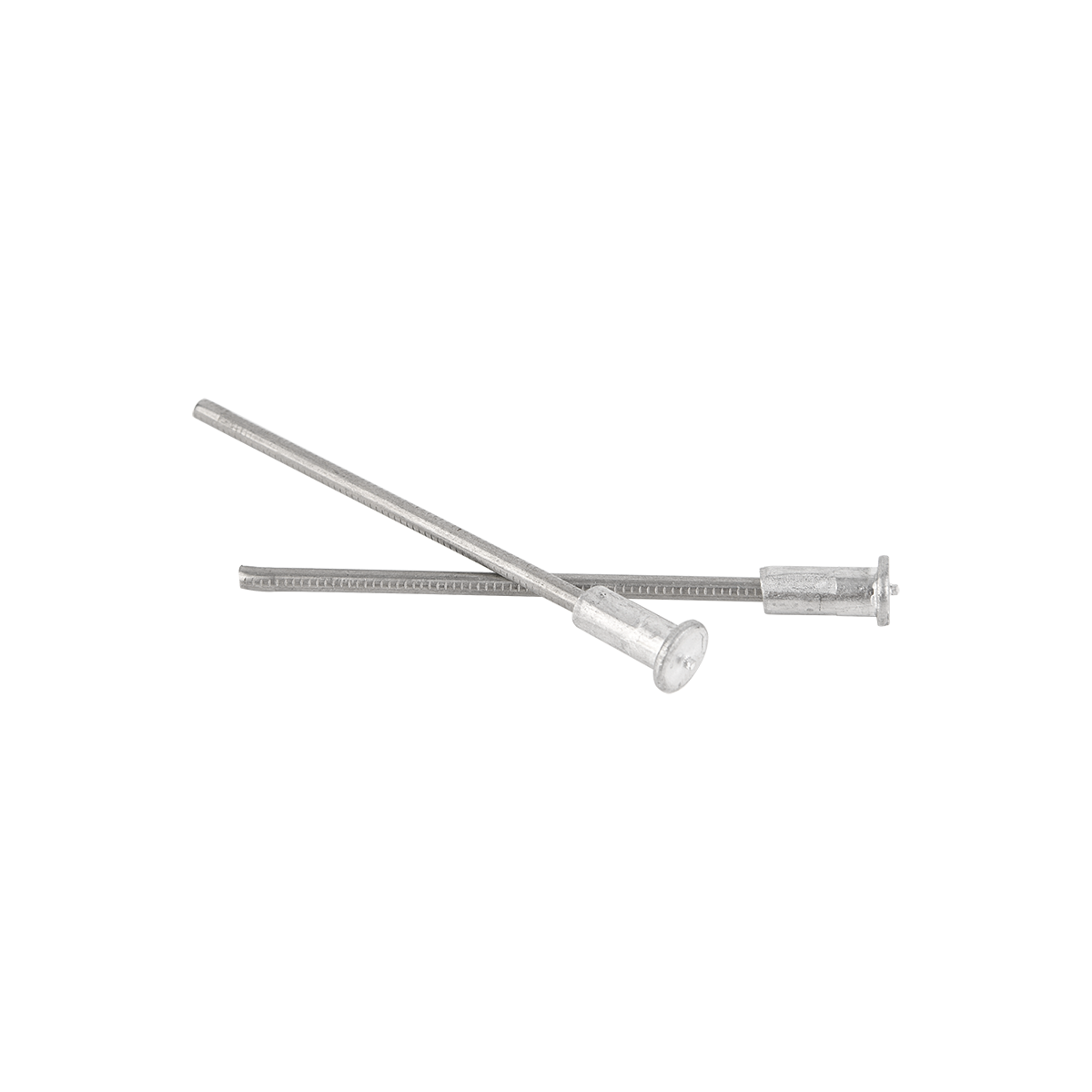

Adhesive Insulation Pin

Author: admin Date: 2024-08-16 15:46:44 Category: INDUSTRY NEWS

Adhesive insulating needle is a specially designed electronic component widely used in various electrical and electronic devices. The main characteristics of this needle are its insulation performance and adhesive properties, which give it unique advantages in many applications. This article will provide a detailed introduction to the characteristics, working principles, application fields, and importance of viscous insulation needles in modern industry.

Characteristics and working principle

Adhesive insulating needles are usually made of high-quality insulating materials, such as ceramics, plastics, or other composite materials. These materials not only have good insulation properties, but also have a certain degree of viscosity, allowing the needle to maintain a stable position when in contact with the surface. This design helps prevent current leakage and short circuits, thereby improving the safety and reliability of the entire system.

The working principle of adhesive insulating needles is based on their special physical structure and material properties. When current passes through a conductor, a viscous insulating needle can effectively isolate the current and guide it to a designated path. Meanwhile, the adhesive properties ensure good contact between the needle and the contact surface, avoiding arcing or sparks caused by looseness or movement.

application area

The application range of adhesive insulating needles is very wide, covering various fields from household appliances to industrial equipment. Here are some main application scenarios:

1. Household appliances : In household appliances such as rice cookers, microwave ovens, washing machines, etc., adhesive insulation needles are used to protect the safety of circuits and users, prevent current leakage and electric shock accidents.

2. Industrial equipment : Adhesive insulating needles are widely used in various mechanical equipment and power systems in factories and workshops to ensure the normal operation of equipment and the safety of operators.

3. Medical Equipment : In medical equipment, adhesive insulated needles are used to protect the safety of patients and medical personnel, and prevent harm to the body from electrical currents.

4. Communication equipment : In communication equipment, adhesive insulation needles are used to protect circuit boards and other electronic components from electromagnetic interference and signal leakage.

importance

The importance of adhesive insulating needles in modern industry is self-evident. Firstly, it improves the safety of electrical and electronic equipment, reduces the risk of current leakage and short circuits, thereby lowering the probability of fire and other safety accidents. Secondly, the use of adhesive insulation needles extends the service life of the equipment and reduces maintenance and repair costs. Finally, the high efficiency and reliability of adhesive insulating needles make them a key component in many high-tech products and systems.

In short, as an important electronic component, adhesive insulating needles play an indispensable role in modern industry. Its unique design and functionality have enabled it to be widely used in various electrical and electronic devices, providing us with safety guarantees and convenient conditions for our lives and work. In the future, with the advancement of technology and the growth of demand, adhesive insulating needles will continue to develop and improve, making greater contributions to the development of human society.