Insulation Pins selection

Author: admin Date: 2024-08-09 16:27:19 Category: INDUSTRY NEWS

When choosing Insulation Pins, the following key factors need to be carefully considered:

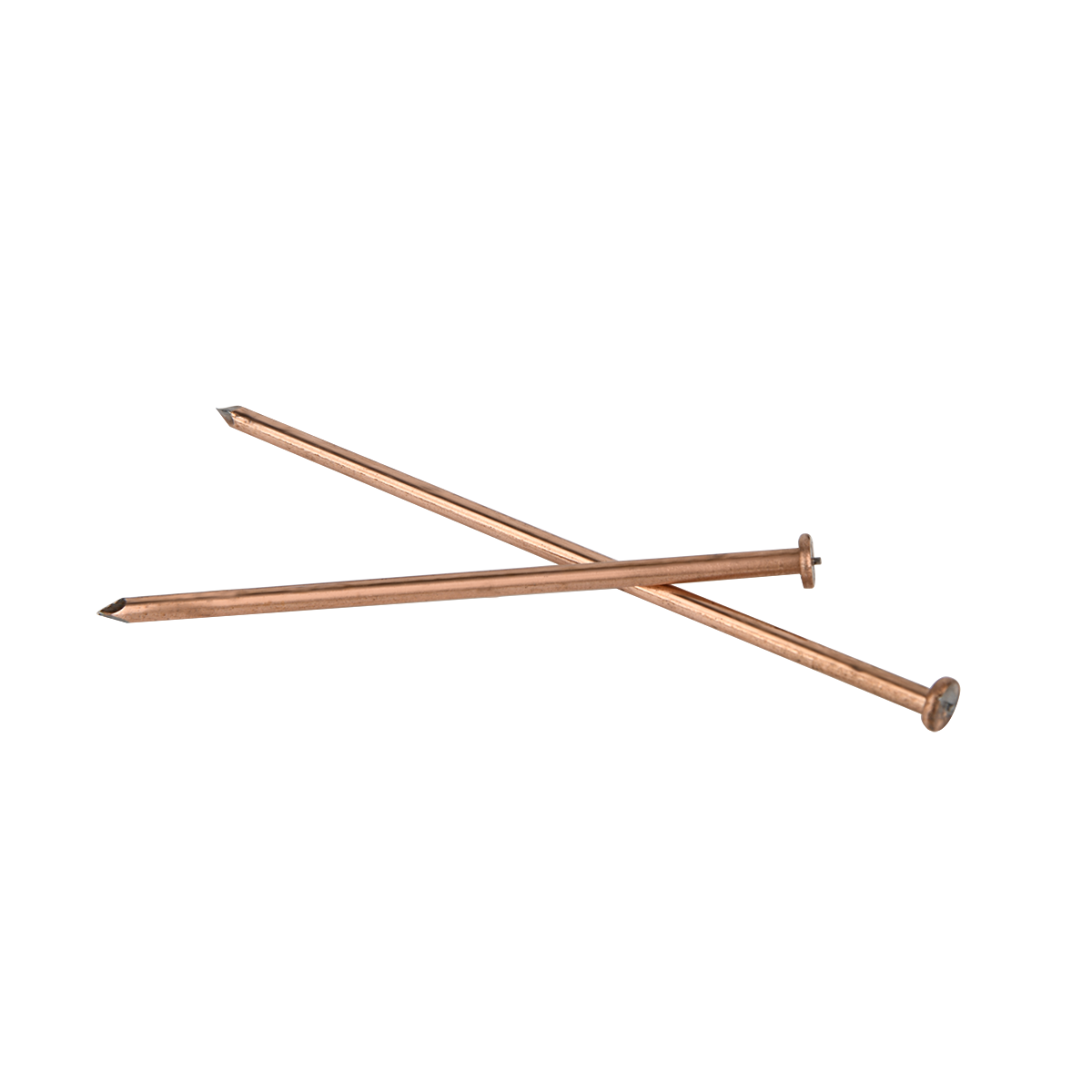

Material quality: High quality materials are the foundation for ensuring the performance and lifespan of insulation nails. Stainless steel material has excellent corrosion resistance and is suitable for use in humid and corrosive environments; Galvanized steel material performs well in general environments and has relatively low costs. To check the purity of the material and the quality of surface treatment, avoid selecting products that are prone to rusting or have insufficient strength.

For example, if it is used for building insulation by the sea, stainless steel insulation nails should be preferred to resist salt erosion caused by sea winds.

Size specifications: Select insulation nails of appropriate length and diameter based on the thickness and weight of the insulation material, as well as the material and strength of the base layer. Nails that are too long or too short may affect the fixing effect.

For example, for thick insulation materials, longer and larger diameter insulation nails need to be selected to provide sufficient support.

Nail head shape: Different nail head shapes can affect the stability of fixation and the adhesion to insulation materials. Common nail heads include round, square, and barbed. A nail head with spikes can better prevent the nail from being pulled out.

For example, in situations where insulation materials are prone to loosening, choosing insulation nails with backstitch can enhance the fixing effect.

Load capacity: Consider the load that the insulation nail needs to bear, including the self weight of the insulation material, external forces such as wind, etc. Ensure that the load capacity of the selected insulation nail is greater than the actual pressure it may withstand.

For example, in the external wall insulation of high-rise buildings, due to the influence of strong wind, it is necessary to choose insulation nails with strong load capacity.

Brand reputation: Choosing insulation nails produced by well-known brands and manufacturers with good reputations can usually ensure product quality and after-sales service.

Brand reputation can be evaluated by viewing user reviews, industry recommendations, and product certifications.