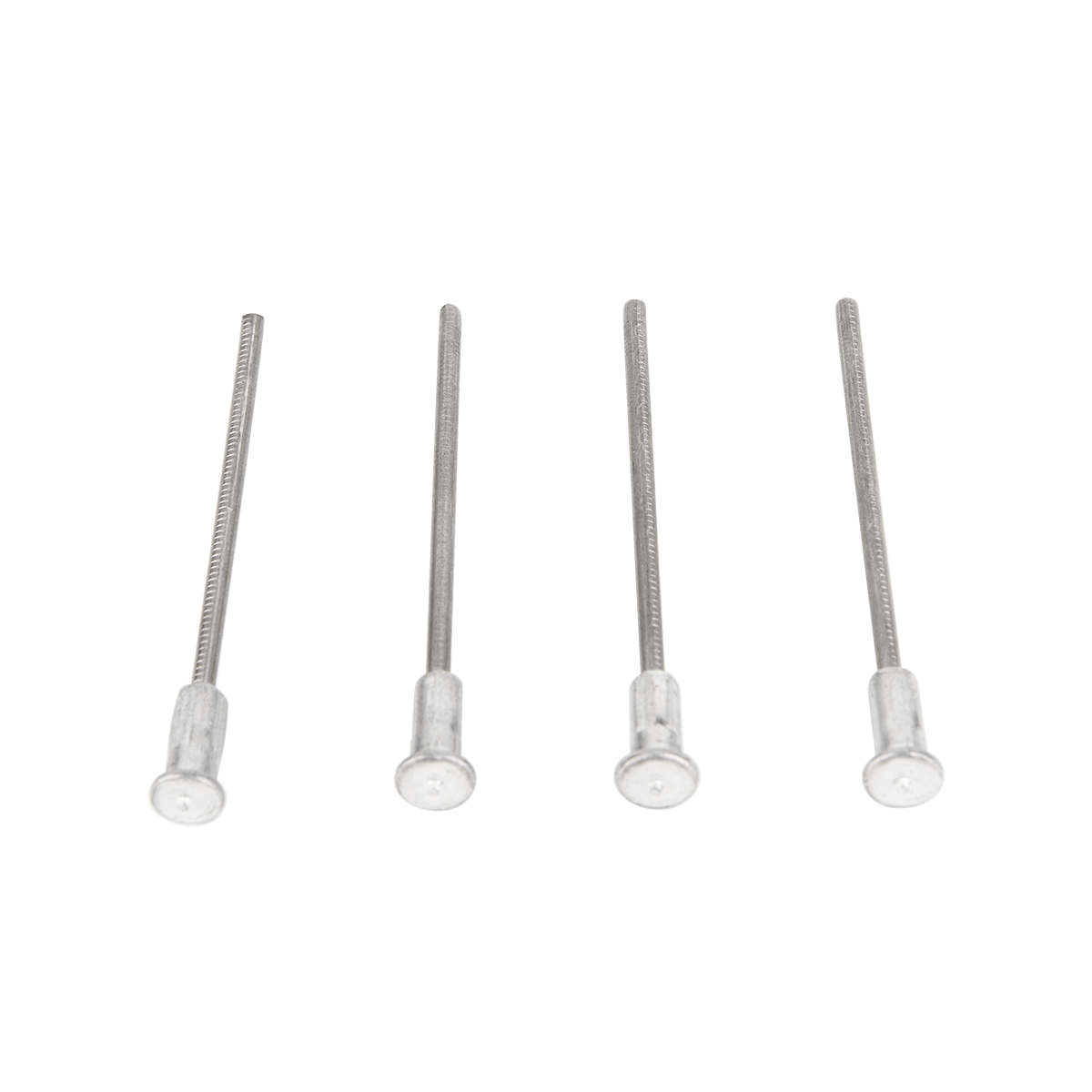

Standard Insulation Pin

Author: admin Date: 2024-08-16 15:48:15 Category: INDUSTRY NEWS

Standard insulated needles are fasteners widely used in the power, communication, and construction industries, designed to provide reliable electrical isolation and mechanical fixation. This type of insulating needle usually consists of two parts: one is a metal needle or screw used to penetrate and fix wires or cables; The other part is insulation material, such as plastic or ceramic, used to prevent current from passing through metal nails to other objects.

The design of standard insulation needles strictly follows international and national standards, such as China's GB standards, International Electrotechnical Commission (IEC) standards, etc. These standards specify the size, material, performance requirements, and testing methods of insulation needles to ensure their safety and reliability in various application environments.

In the power system, standard insulation needles are often used to fix high or low voltage wires, prevent current leakage, and ensure the normal operation of the power grid. In the communication industry, they are used to secure communication cables and ensure the stability of signal transmission. In the field of construction, standard insulation needles are used to fix various electrical circuits and ensure electrical safety inside buildings.

In order to ensure the quality and performance of standard insulation needles, manufacturers usually conduct a series of rigorous tests, including insulation resistance testing, withstand voltage testing, mechanical strength testing, etc. In addition, users also need to pay attention to maintenance and upkeep during installation and use, regularly check the condition of the insulation pins, and replace them in a timely manner if damaged or aged, to avoid safety hazards.