Characteristics of Insulation Pins

Author: admin Date: 2024-08-09 16:25:52 Category: INDUSTRY NEWS

Insulation pins have the following significant characteristics:

Excellent fixing performance: Insulation Pins are typically designed with sharp tips and specific shapes that can easily penetrate insulation materials and firmly fix them to the surface of the substrate. Its strong grip ensures that the insulation material will not loosen or fall off under various conditions. For example, in areas with strong winds, insulation nails can effectively prevent the insulation layer from being blown off by the wind.

Corrosion resistance: Generally made of stainless steel, galvanized steel or other corrosion-resistant materials, it can resist chemical erosion and oxidation in harsh environments. This allows them to maintain good performance in humid, salt foggy coastal areas or industrial environments with severe chemical pollution.

Good thermal insulation performance: Although it is made of metal material, due to its small volume and reasonable design, its impact on heat transfer is minimal, and it will not form a significant thermal bridge in the insulation system, thus ensuring the overall thermal insulation effect.

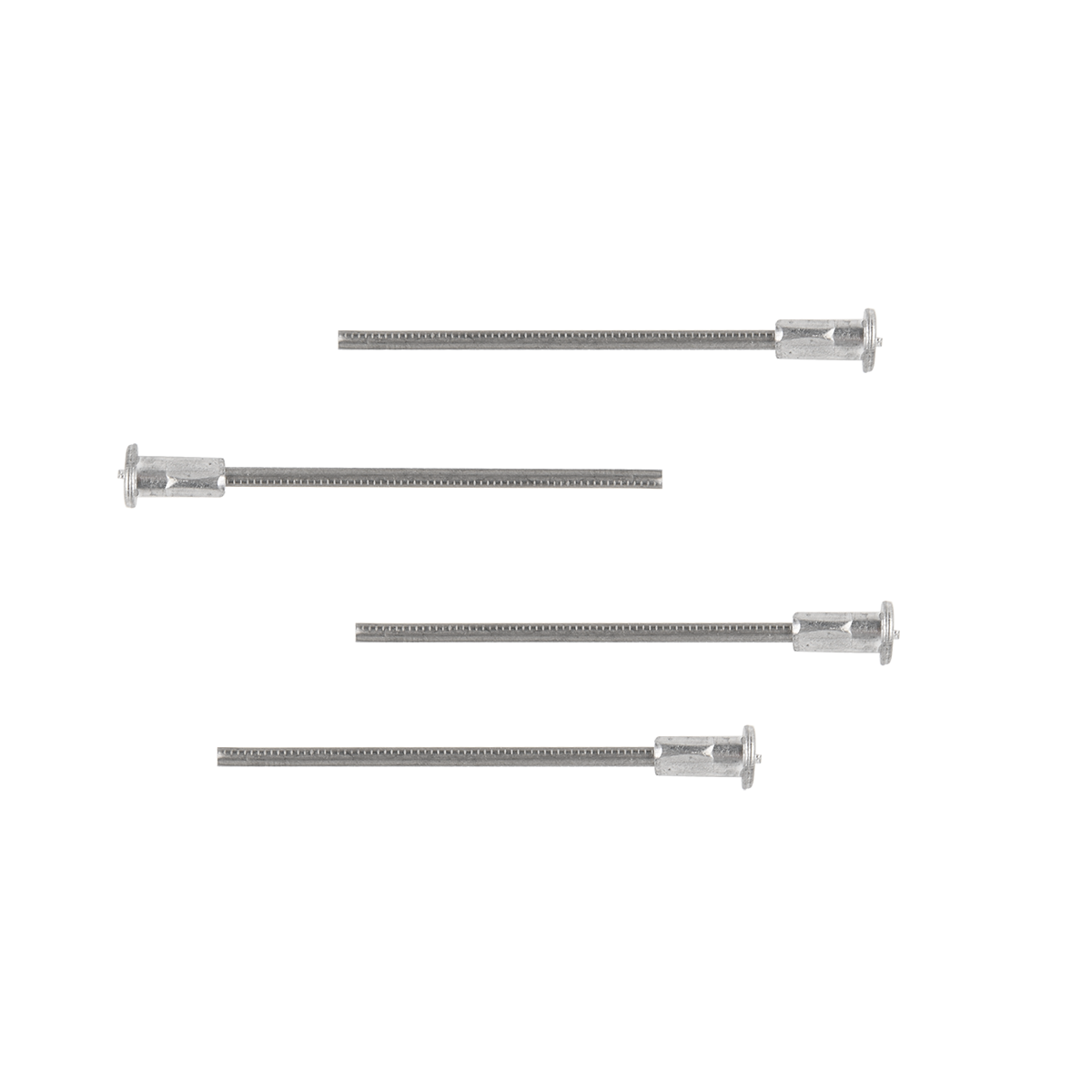

Diversified specifications and shapes: In order to adapt to different insulation materials and construction requirements, Insulation Pins have multiple specifications and shapes to choose from. There are short and thick ones used for lightweight insulation materials, as well as long and thin ones suitable for thick insulation layers; There are also designs with barbed or spiral patterns to enhance the fixation effect.

Convenient and fast construction: The installation process is relatively simple, and specialized tools such as air guns or electric drills can be used to quickly fix it in the predetermined position, greatly improving construction efficiency.