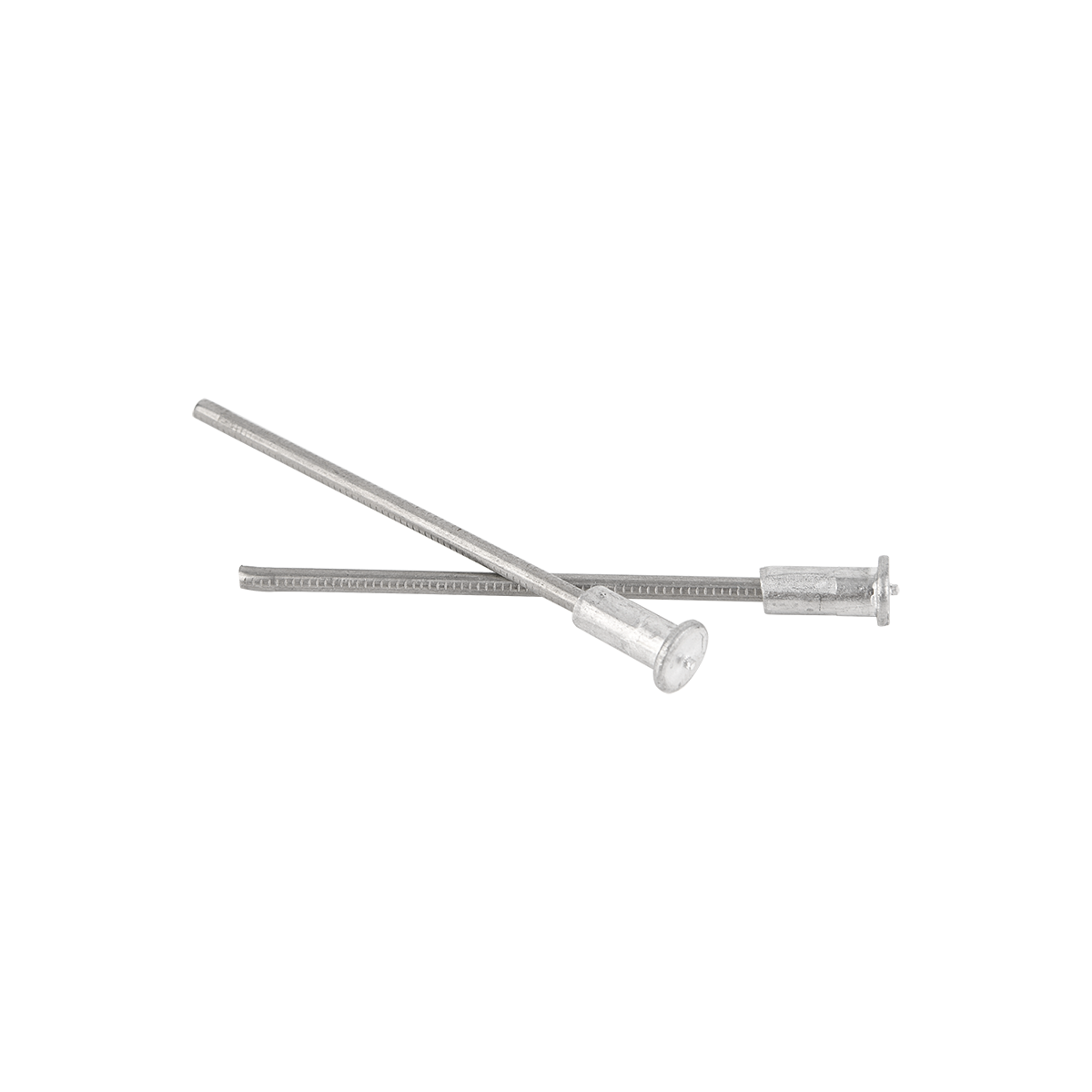

Common Failures of Self-Adhesive Insulation Pins and Their Solutions

Author: admin Date: 2024-08-16 15:50:39 Category: INDUSTRY NEWS

While self-adhesive insulation pins are designed to offer reliable performance, there are certain common issues that can arise during their use. Understanding these problems and knowing how to address them is crucial for maintaining the integrity of the insulation.

One common failure is the pins coming loose from the surface. This can happen if the surface was not properly prepared before installation, or if the adhesive was exposed to extreme temperatures or moisture. To solve this, re-clean the surface and apply a new pin or use an adhesive enhancer.

Another issue could be the pins not providing adequate insulation. This might be due to incorrect placement, insufficient quantity of pins, or pins of the wrong size. In such cases, reposition or add more pins as needed, and ensure they are the correct size for the insulation material.

Sometimes, the adhesive may lose its stickiness over time. This could be a result of aging or exposure to harsh chemicals. To remedy this, you can try cleaning the pin and the surface and applying a fresh layer of adhesive.

If the pins are damaged or deformed, it can compromise their functionality. This might occur due to physical impact or excessive stress. Replace any damaged pins promptly to maintain the insulation's effectiveness.

For example, in an industrial setting where there is constant vibration, the pins might get deformed. Regular inspections and timely replacements are essential.

In some cases, the insulation material itself may start to deteriorate around the pins. This could be due to incompatible materials or poor installation technique. Inspect the insulation regularly and address any signs of deterioration by correcting the installation or using a more compatible insulation material.

By being aware of these common failures and having the appropriate solutions at hand, you can ensure that the self-adhesive insulation pins continue to perform effectively and provide the desired insulation.