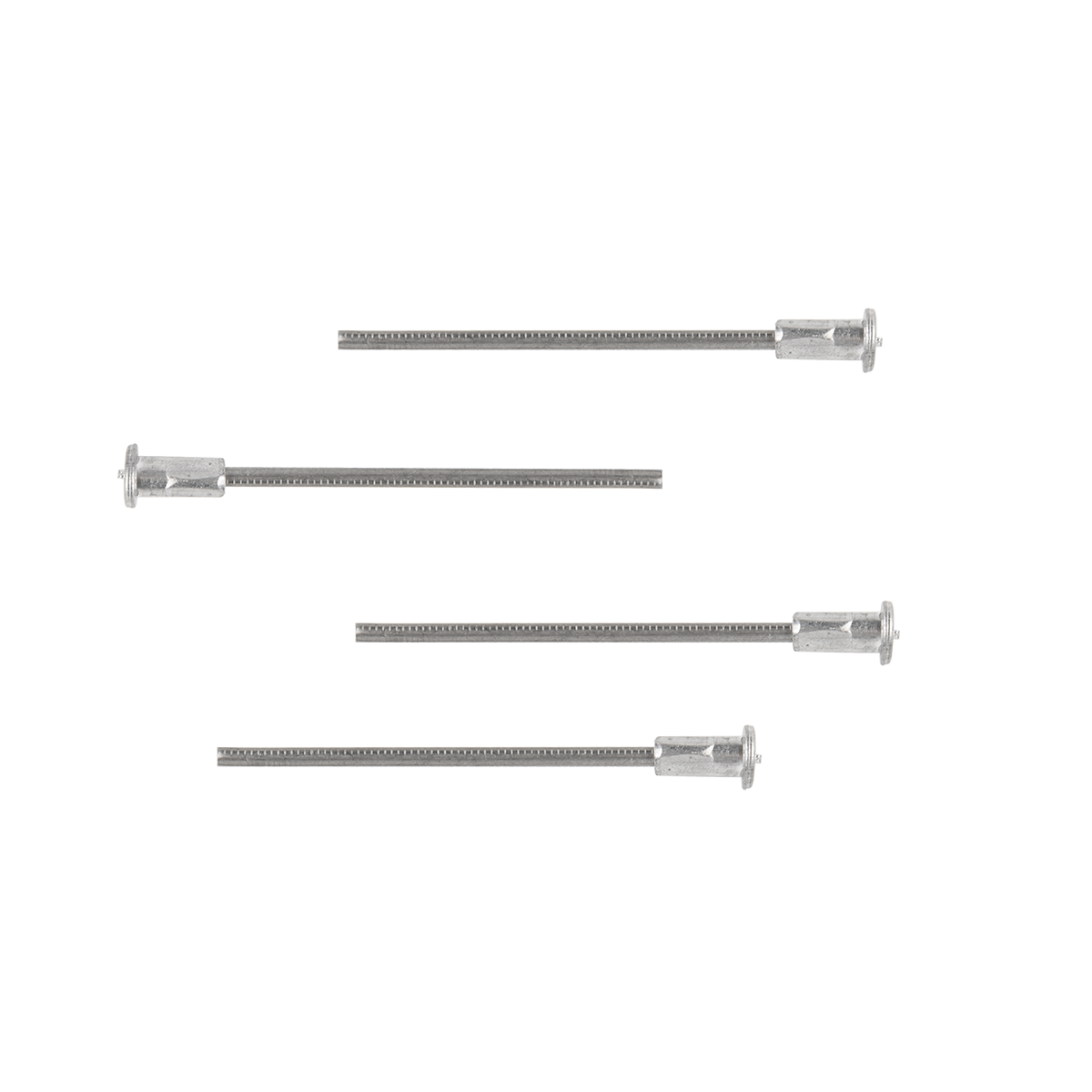

Common Types of Insulation Pins

Author: admin Date: 2024-08-09 16:28:22 Category: INDUSTRY NEWS

Ordinary insulation nail: composed of a metal rod and a plastic or rubber disc, it is the most common and basic type. The metal rod is usually made of galvanized steel or stainless steel, and the disc plays a role in increasing the contact area and preventing the insulation material from sliding down.

For example, it is widely used in general building exterior wall insulation.

Inverted insulation nails: Inverted spikes are set on the metal rod to enhance the friction with the base layer and insulation material, and improve the fixing effect.

Commonly used in situations with strong wind or high requirements for fixation, such as insulation engineering for high-rise buildings.

Expansion type insulation nail: By expanding when driven into the base layer, it achieves a more secure fixation.

Suitable for base layers with loose texture, such as lightweight bricks or hollow blocks.

Welding type insulation nail: It needs to be fixed on the metal substrate by welding, and has high strength and stability.

Commonly used for insulation and fixation of industrial equipment.

Plastic insulation nail: made of high-strength plastic, with good corrosion resistance and insulation performance, suitable for environments with corrosion risks to metals.

For example, it may be used in insulation engineering in chemical factories.