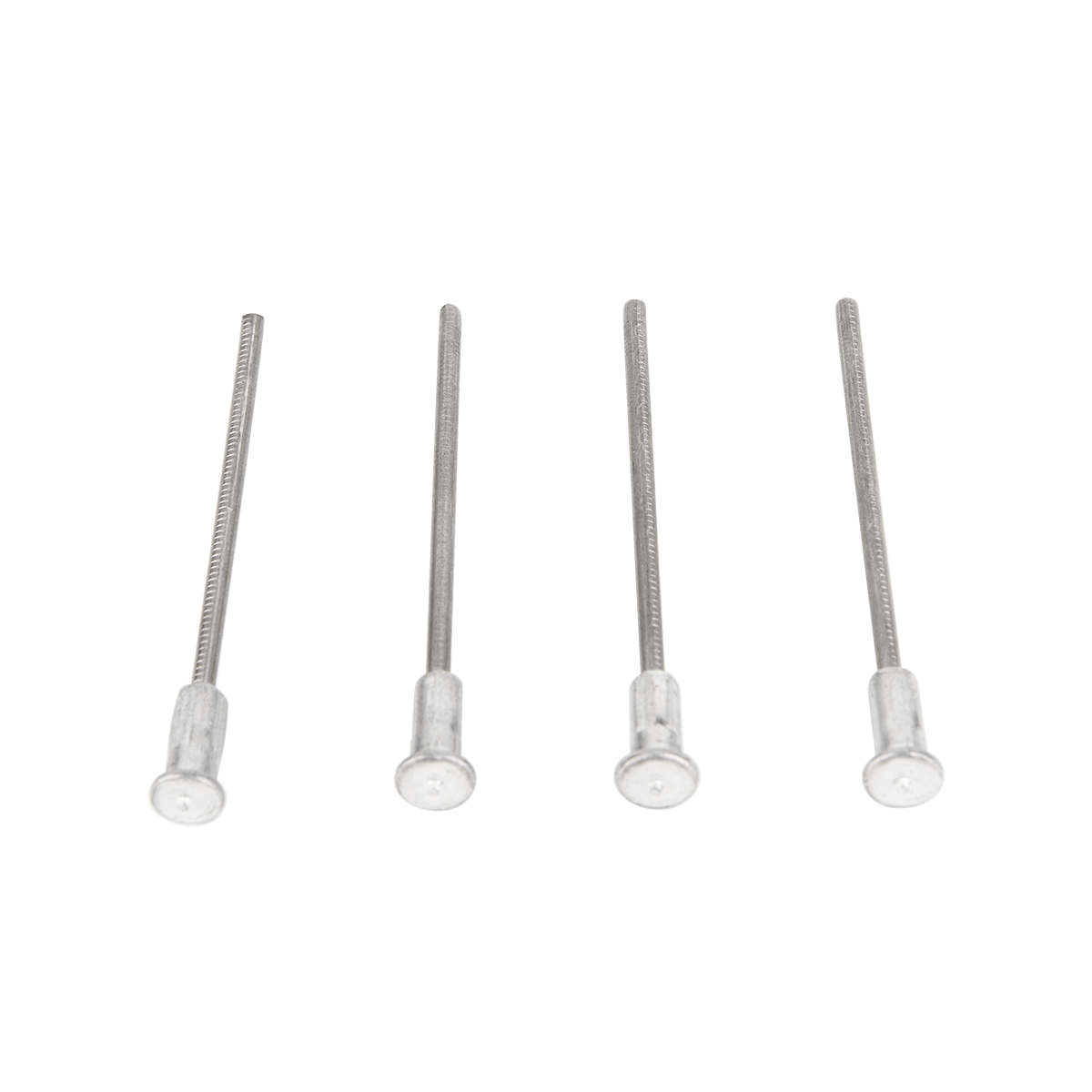

Cupped Head Insulation Pins

Author: admin Date: 2024-08-16 16:00:43 Category: INDUSTRY NEWS

Cupped head insulation pins are a specialized type of fastener that offers distinct advantages in insulation applications. The cupped head design is not just a cosmetic feature but serves important functional purposes.

The cupped shape of the head provides increased surface area contact with the insulation material. This helps distribute the force exerted by the pin more evenly, reducing the risk of damaging the insulation during installation or over time. It also enhances the stability and security of the attachment.

For instance, in roofing insulation projects, cupped head insulation pins can prevent the insulation from being punctured or compressed too much at the point of contact. This maintains the integrity of the insulation's structure and its insulating properties.

The material used for these pins is often chosen for its durability and resistance to environmental factors. Common materials include stainless steel or other alloys that can withstand moisture, temperature variations, and chemical exposure.

In a marine environment, where saltwater and humidity are prevalent, cupped head insulation pins made of corrosion-resistant materials ensure the longevity of the insulation system on ships or offshore structures.

The cupped head design also makes these pins more visually appealing in certain applications where the insulation is visible. This can be important in architectural or design-driven projects where aesthetics matter.

In a commercial building with exposed ductwork and insulation, the use of cupped head insulation pins can contribute to a neater and more finished look.

Furthermore, the shape of the cupped head can sometimes aid in the alignment and positioning of the insulation, making the installation process more efficient and accurate.

Overall, cupped head insulation pins combine functionality, durability, and aesthetic considerations, making them a valuable choice in a wide range of insulation installations.