Daily maintenance tips for Stuck Up Insulation Pins devices

Author: admin Date: 2024-08-09 17:08:09 Category: INDUSTRY NEWS

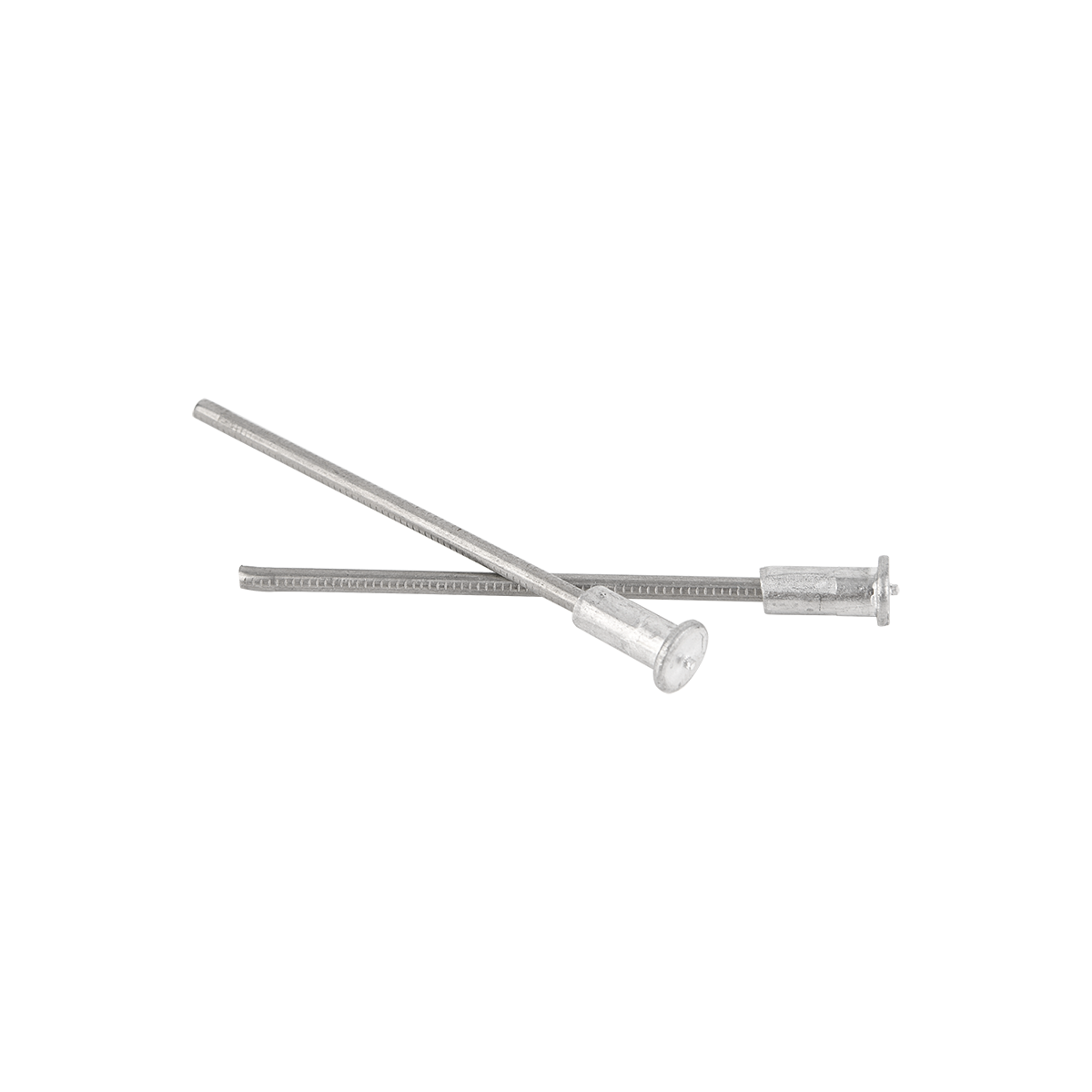

Stuck Up Insulation Pins devices play a crucial role in the industrial and construction fields, used to secure and support various insulation materials. To ensure its long-term efficient operation, daily maintenance is essential. Here are some effective daily maintenance techniques:

1. Regular cleaning

Regular cleaning is the foundation for maintaining the normal operation of Stuck Up Insulation Pins equipment. The device is prone to accumulating dust, dirt, and other impurities during use, which may affect its performance. It is recommended to conduct a comprehensive cleaning at least once a week, using a clean cloth and appropriate cleaning agents to wipe the surface of the equipment to ensure that there are no residues.

2. Check fasteners

The equipment may experience loose fasteners during operation, which increases the risk of equipment failure. Therefore, it is very important to regularly inspect all fasteners and ensure that they are secure and reliable. It is recommended to conduct a fastener inspection once a month and promptly address any issues found.

3. Lubrication and maintenance

Proper lubrication can reduce equipment wear and prolong its service life. According to the recommendations of the equipment manufacturer, select appropriate lubricants and regularly lubricate various moving parts of the equipment. Normally, it is ideal to conduct comprehensive lubrication and maintenance once every quarter.

4. Regularly check electrical connections

Electrical connection issues may cause equipment to malfunction and even lead to safety accidents. Regularly check the electrical connections of the equipment to ensure that all wiring is secure and undamaged. It is recommended to conduct a detailed electrical inspection every six months and promptly repair any problems found.

5. Spare parts management

During long-term use, certain components of the equipment may wear out or be damaged. To reduce downtime, it is recommended to stock up on some commonly used spare parts such as screws, gaskets, seals, etc. In this way, when problems arise, the device can be quickly replaced and restored to operation.