FG Insulation Pins and Their Alternatives

Author: admin Date: 2024-08-16 15:52:35 Category: INDUSTRY NEWS

FG Insulation Pins are commonly used in insulation applications for their specific properties and functionality. However, there are also alternative options available depending on the specific requirements of the project.

FG Insulation Pins are known for their strength, durability, and good insulation properties. They are often made of fiberglass-reinforced materials, which provide resistance to heat, moisture, and chemicals. These pins are suitable for a wide range of insulation setups, especially in industrial and commercial settings.

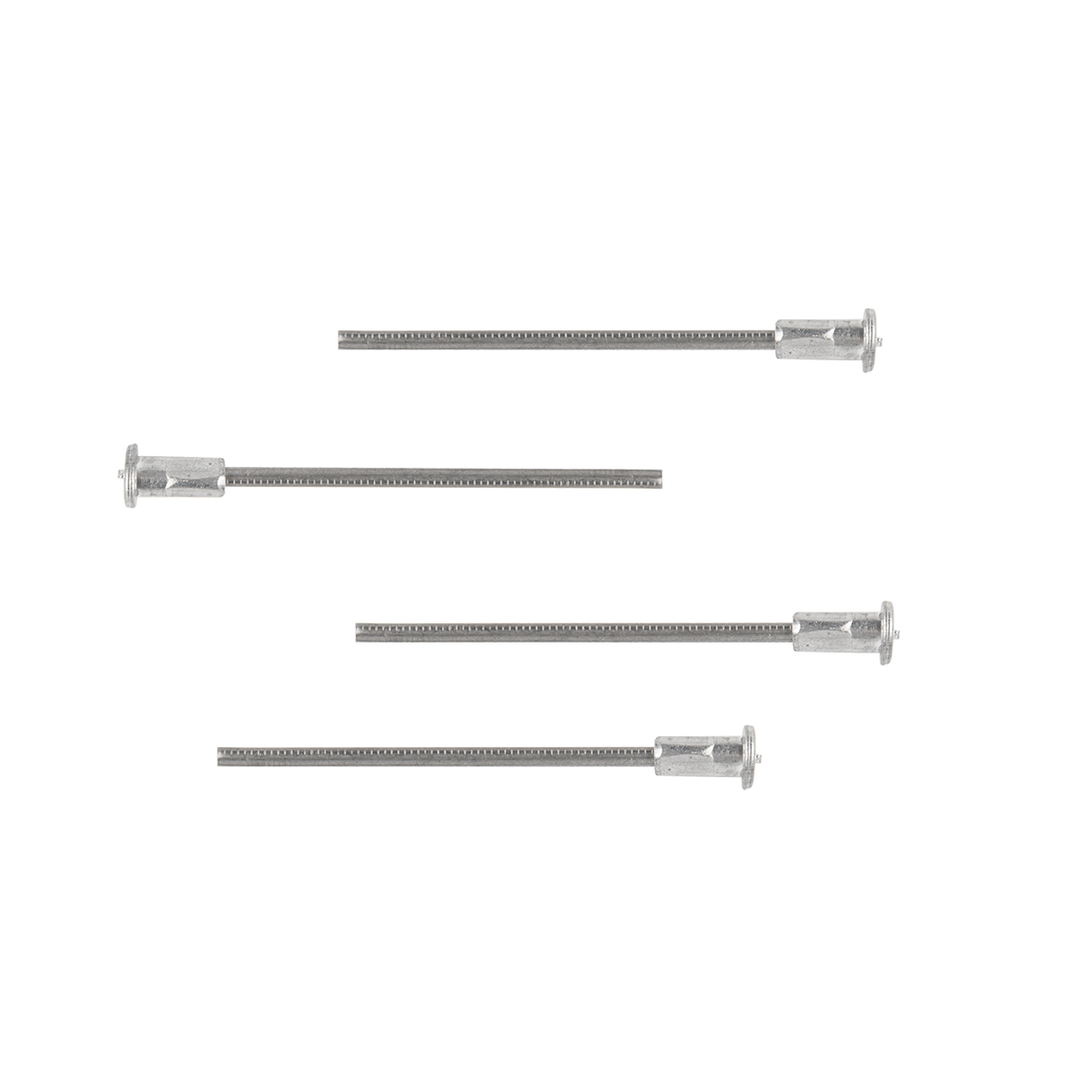

One alternative to FG Insulation Pins is metal insulation pins. These are typically made of stainless steel or other corrosion-resistant metals. Metal pins offer high strength and can withstand heavy loads. They are often used in applications where mechanical stability is crucial, such as in large-scale insulation projects or in environments with high vibration.

Another option is plastic insulation pins. These are usually made from polymers like nylon or polypropylene. Plastic pins are lightweight and can offer good insulation properties. They are often chosen for applications where weight is a consideration or where the insulation material is more delicate and requires a gentler attachment method.

For example, in some electronic equipment insulation, plastic pins might be preferred to avoid any potential electrical conductivity issues that could occur with metal pins.

Biodegradable insulation pins are also emerging as an alternative. These are made from sustainable materials and are environmentally friendly. They are suitable for projects where sustainability is a priority.

When choosing between FG Insulation Pins and their alternatives, factors such as the type of insulation material, the environment in which they will be used, the load-bearing requirements, and the project's sustainability goals need to be considered.