How to Choose the Appropriate Insulation Pins?

Author: admin Date: 2024-08-16 15:54:27 Category: INDUSTRY NEWS

Selecting the right insulation pins is a crucial decision that can significantly impact the effectiveness and longevity of your insulation system. Here are several key factors to consider when making your choice.

Firstly, assess the type of insulation material you'll be working with. Different insulation materials may require specific types of pins for optimal attachment and performance. For instance, if you're using a soft and flexible insulation, you'll need pins with a gentle grip to avoid damaging the material. On the other hand, for denser and more rigid insulation, stronger and sharper pins might be necessary.

The operating environment is another important factor. If the insulation will be exposed to high temperatures, moisture, chemicals, or mechanical stress, you need pins that can withstand these conditions. For example, in a chemical processing plant, pins made of corrosion-resistant materials like stainless steel or specialized alloys would be more suitable.

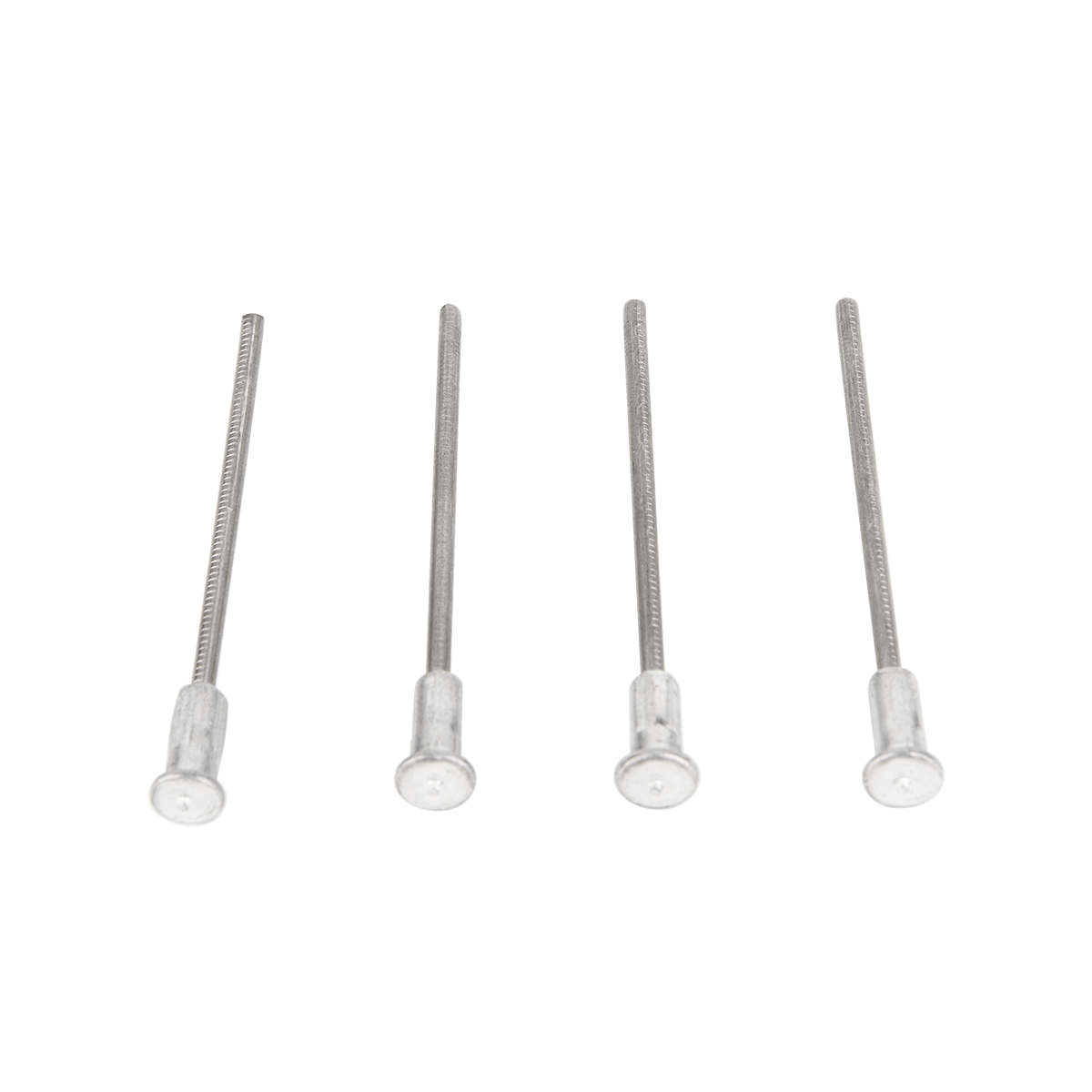

The size and shape of the pins matter too. Consider the thickness and width of the insulation and the available space for pin installation. Pins that are too long or too short may not provide proper support or could cause damage. Also, the shape of the pin head can affect its holding power and ease of installation.

The adhesive or fastening method of the pins should also be evaluated. Some pins have self-adhesive backs, while others require mechanical fastening. The quality and strength of the adhesive or the type of mechanical fastener can determine the reliability of the pin's attachment.

Furthermore, look at the load-bearing capacity of the pins. This is especially important in applications where the insulation may be subject to heavy pressure or weight. Insufficient load-bearing capacity could lead to the insulation sagging or coming loose over time.

For example, in a ceiling insulation project, you need to ensure the pins can support the weight of the insulation and any potential loads, such as from ductwork or fixtures.

Finally, consider your budget. While it's important to find cost-effective options, don't sacrifice quality for a lower price. High-quality insulation pins may cost more initially but can save you money in the long run by providing better performance and durability.

By carefully considering these factors and conducting thorough research, you can make an informed decision and choose the appropriate insulation pins for your specific project requirements.