How to install Lacing Hooks more securely

Author: admin Date: 2024-08-09 17:14:01 Category: INDUSTRY NEWS

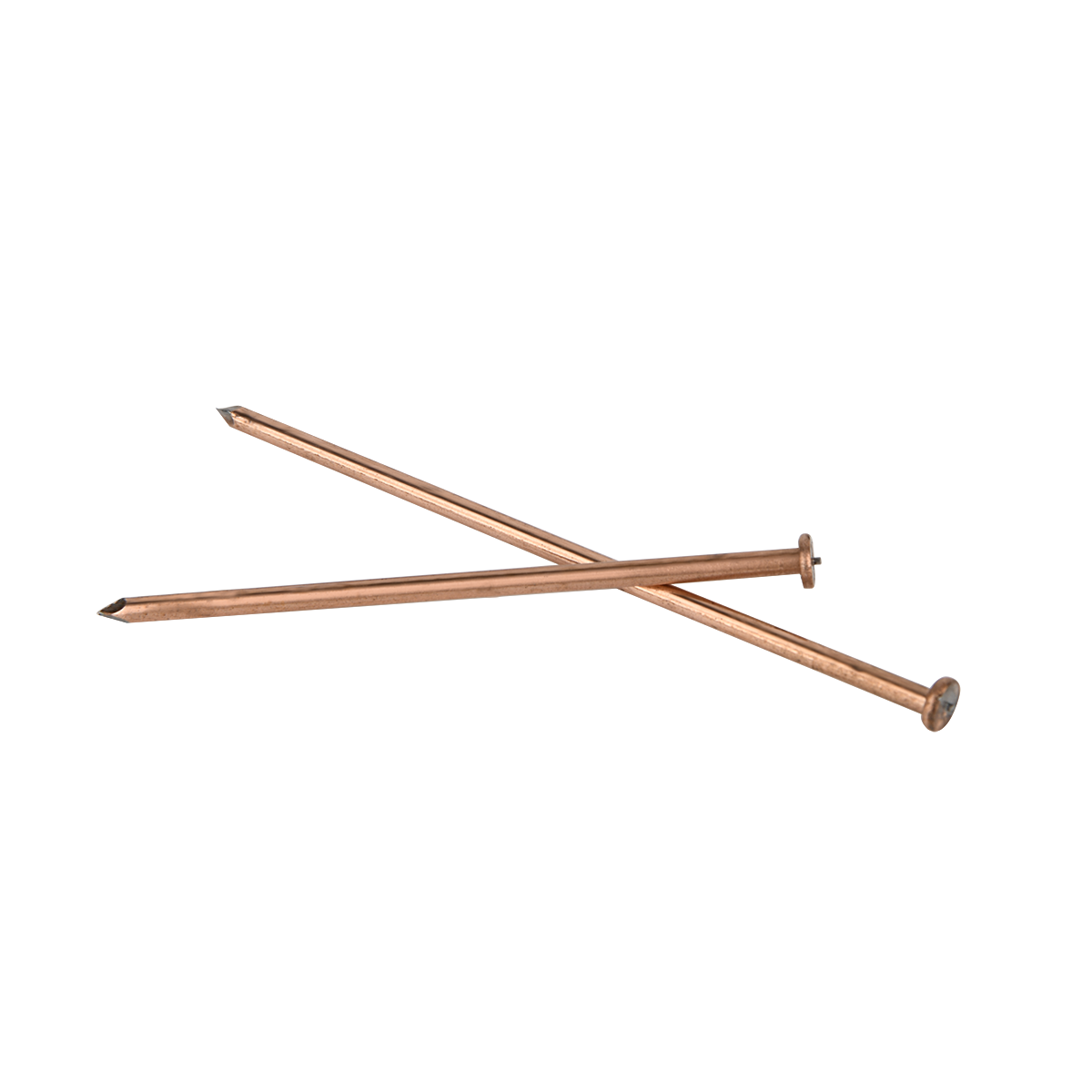

Lacing Hooks are hardware accessories commonly used for connecting and securing conveyor belts. Based on the search results [8] [9] [10], we can learn some methods and techniques on how to install Lacing Hooks more securely.

Choose appropriate tools and materials

Firstly, it is crucial to choose the appropriate Lacing Hooks and installation tools. Ensure that the selected Lacing Hooks material is sturdy, such as stainless steel or high-strength alloy steel, to ensure their durability and tensile performance. In addition, choosing installation tools that match the Lacing Hooks, such as specialized hook installation pliers and fastening wrenches, can improve installation efficiency and firmness.

Preparation work

Before installing Lacing Hooks, ensure that the connection points of the conveyor belt are clean, dry, and undamaged. If there is any damage or wear, it should be repaired or replaced in a timely manner to ensure the strength and stability of the connecting parts. In addition, check whether the size and quantity of Lacing Hooks meet the requirements to ensure that there will be no shortage or mismatch during the installation process.

Correct installation steps

1. Positioning and Marking: Determine the installation position of the Lacing Hooks and make clear markings with a marking pen. Ensure that the positions of each Lacing Hook are evenly distributed to balance the force.

2. Pre drilling: Use an appropriate drill bit to pre drill holes at the marked locations. Pre drilling can not only reduce the risk of Lacing Hooks breaking during installation, but also improve installation speed and accuracy.

3. Inserting Lacing Hooks: Insert the Lacing Hooks into the pre drilled hole, ensuring they are fully seated and securely fixed. Using specialized installation tools such as hook installation pliers can help you complete this step more easily.

4. Tightening and fixing: Use a tightening wrench or other suitable tool to fasten the Lacing Hooks to the conveyor belt. Ensure that each lacing hook is securely fastened to prevent loosening or detachment during use.

5. Inspection and testing: After installation, conduct a comprehensive inspection and testing to ensure the installation quality and firmness of the Lacing Hooks. Its firmness and stability can be tested by manually pulling or using appropriate testing equipment.

Regular maintenance and inspection

After installation, regularly inspect and maintain the Lacing Hooks to promptly identify and address any potential issues. If any loose or damaged Lacing Hooks are found, they should be tightened or replaced in a timely manner to prevent further damage and accidents.