Insulation Fasteners for Welding

Author: admin Date: 2024-09-02 10:30:27 Category: INDUSTRY NEWS

Insulation fasteners for welding play a crucial role in ensuring the integrity and effectiveness of insulation systems in various industrial applications. These fasteners are specifically designed to securely hold insulation materials in place during the welding process, where high temperatures and mechanical stresses can pose challenges to the stability of the insulation.

One of the key features of insulation fasteners for welding is their ability to withstand extreme temperatures. They are made from materials that can endure the heat generated by welding operations without melting or deforming. This ensures that the insulation remains firmly attached and provides the necessary protection to the underlying structure.

In addition to temperature resistance, these fasteners also offer excellent mechanical strength. They are designed to resist the forces exerted by the welding process, such as vibration and impact. This helps to prevent the insulation from becoming dislodged or damaged, ensuring long-term performance and reliability.

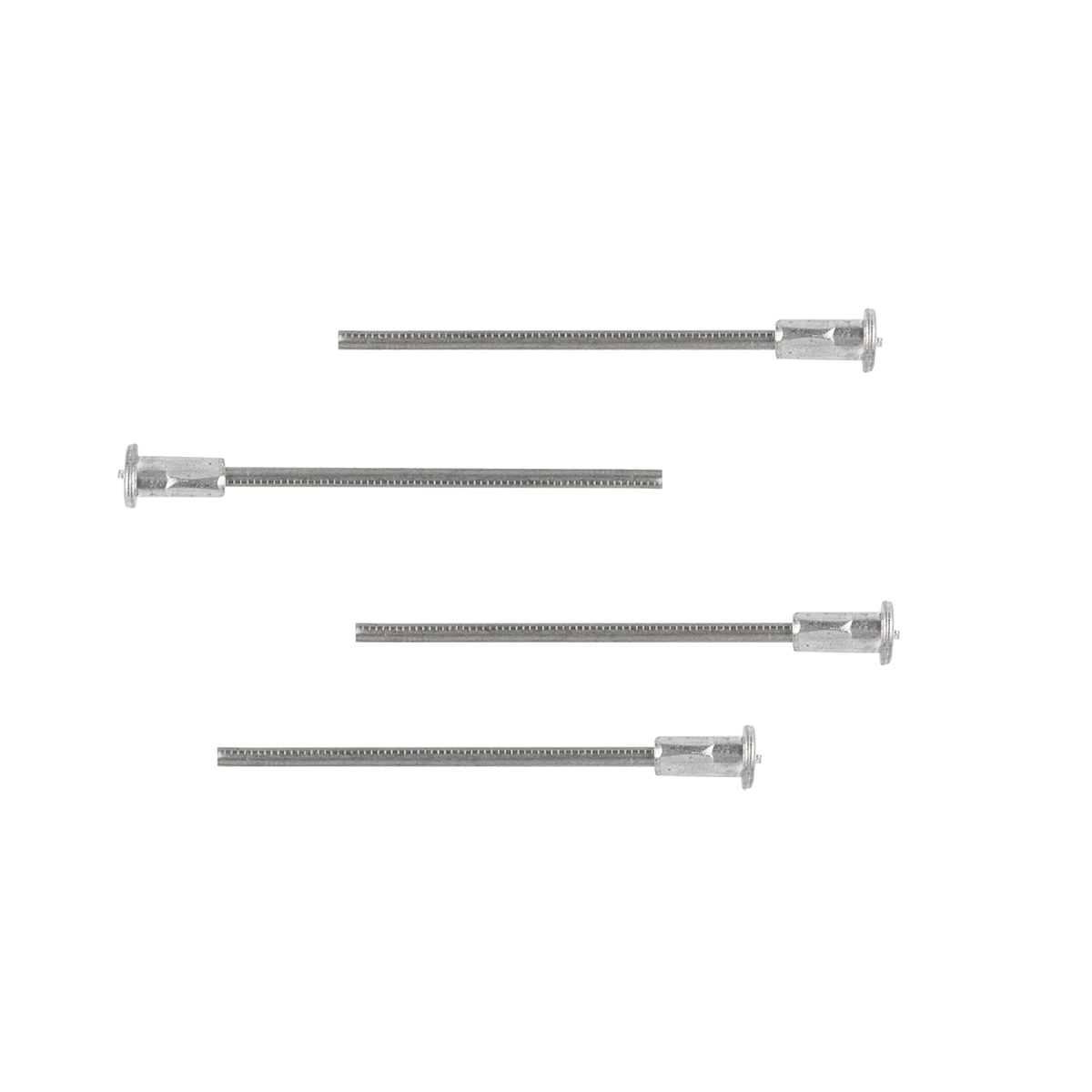

The design of insulation fasteners for welding is often optimized for ease of installation. They may come in various shapes and sizes to fit different insulation materials and installation requirements. Some fasteners may have a threaded design for easy insertion and tightening, while others may use a clip or clamp mechanism for quick and secure attachment.

Moreover, these fasteners are often corrosion-resistant to ensure durability in harsh environments. They can withstand exposure to moisture, chemicals, and other corrosive elements, which is essential for applications in industries such as oil and gas, chemical processing, and power generation.

Overall, insulation fasteners for welding are an essential component of insulation systems in welding applications. Their ability to withstand high temperatures, provide mechanical strength, and offer ease of installation makes them a reliable choice for ensuring the effectiveness and longevity of insulation.