Insulation Pins Welder System

Author: admin Date: 2024-08-16 16:03:56 Category: INDUSTRY NEWS

The insulation pins welder system is a highly specialized and efficient technology used in the insulation industry. This system plays a crucial role in securely attaching insulation materials to various surfaces, ensuring optimal insulation performance and longevity.

The insulation pins welder system typically consists of a power source, a welding gun or electrode, and a control unit. The power source supplies the necessary electrical energy to create the weld, while the welding gun is designed to precisely deliver the welding current to the insulation pins.

One of the significant advantages of this system is its ability to create strong and durable bonds between the insulation pins and the substrate. The welding process fuses the metal of the pins with the underlying material, providing a connection that can withstand mechanical stress, vibration, and environmental factors.

For example, in the construction of industrial facilities, such as chemical plants or refineries, where insulation is critical for maintaining process temperatures and safety, the insulation pins welder system ensures that the insulation remains firmly in place, even in harsh operating conditions.

The control unit of the system allows for precise adjustment of the welding parameters, such as current, voltage, and weld time. This enables operators to customize the welding process based on the type of insulation material, substrate, and specific project requirements.

In automotive manufacturing, the insulation pins welder system is used to attach insulation to engine compartments and interiors. The ability to fine-tune the welding settings ensures consistent and high-quality welds, contributing to noise reduction and thermal management within the vehicle.

Another benefit of this system is its speed and efficiency. Compared to traditional fastening methods, the welding process is often quicker, allowing for faster installation of insulation and reducing project timelines.

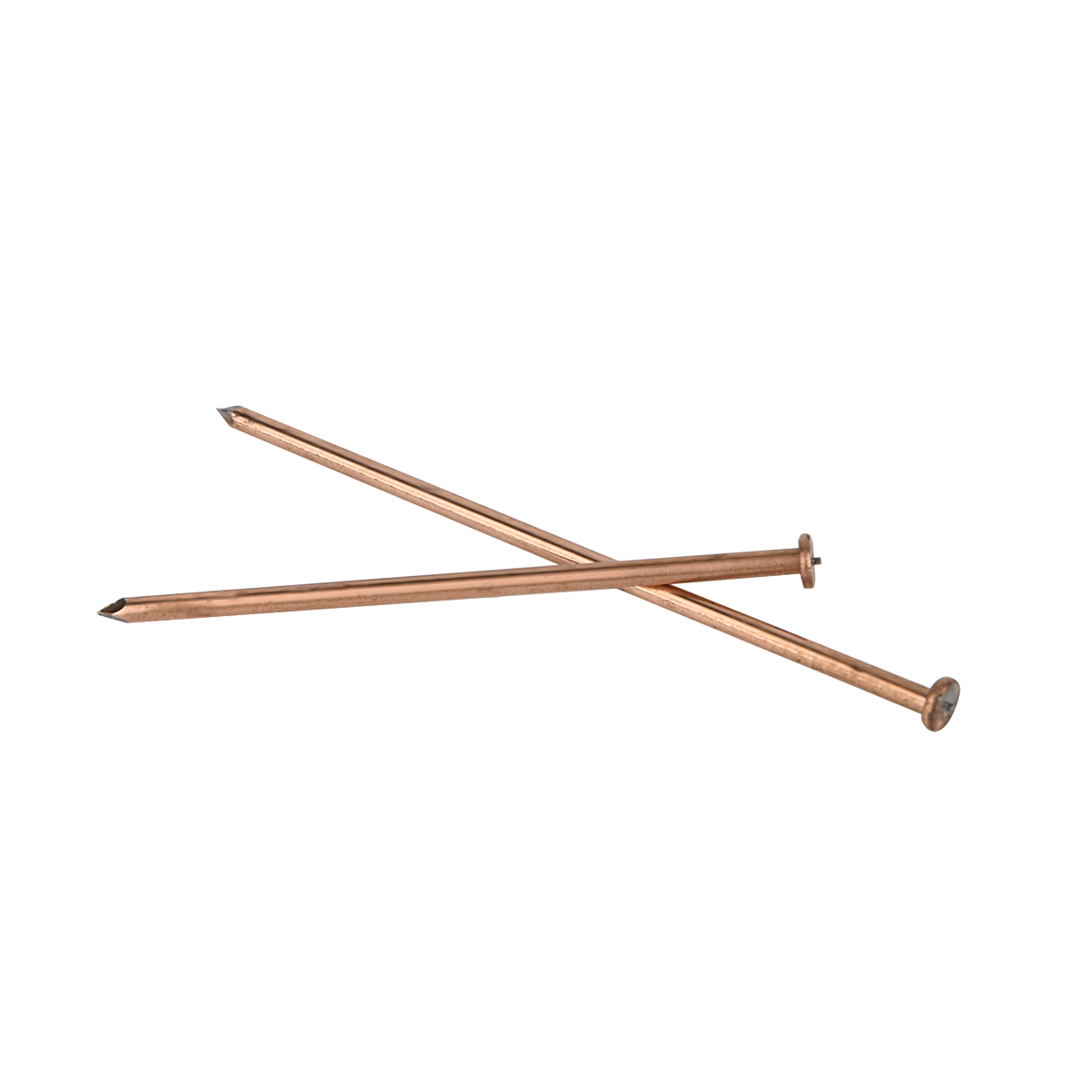

Furthermore, the insulation pins welder system can be used with a wide range of insulation pin materials and sizes, providing flexibility in design and application.

Overall, the insulation pins welder system is a powerful tool that combines strength, precision, and efficiency, making it an indispensable part of modern insulation installation processes in various industries.