Insulation Pins and Stud Welding

Author: admin Date: 2024-08-16 16:01:27 Category: INDUSTRY NEWS

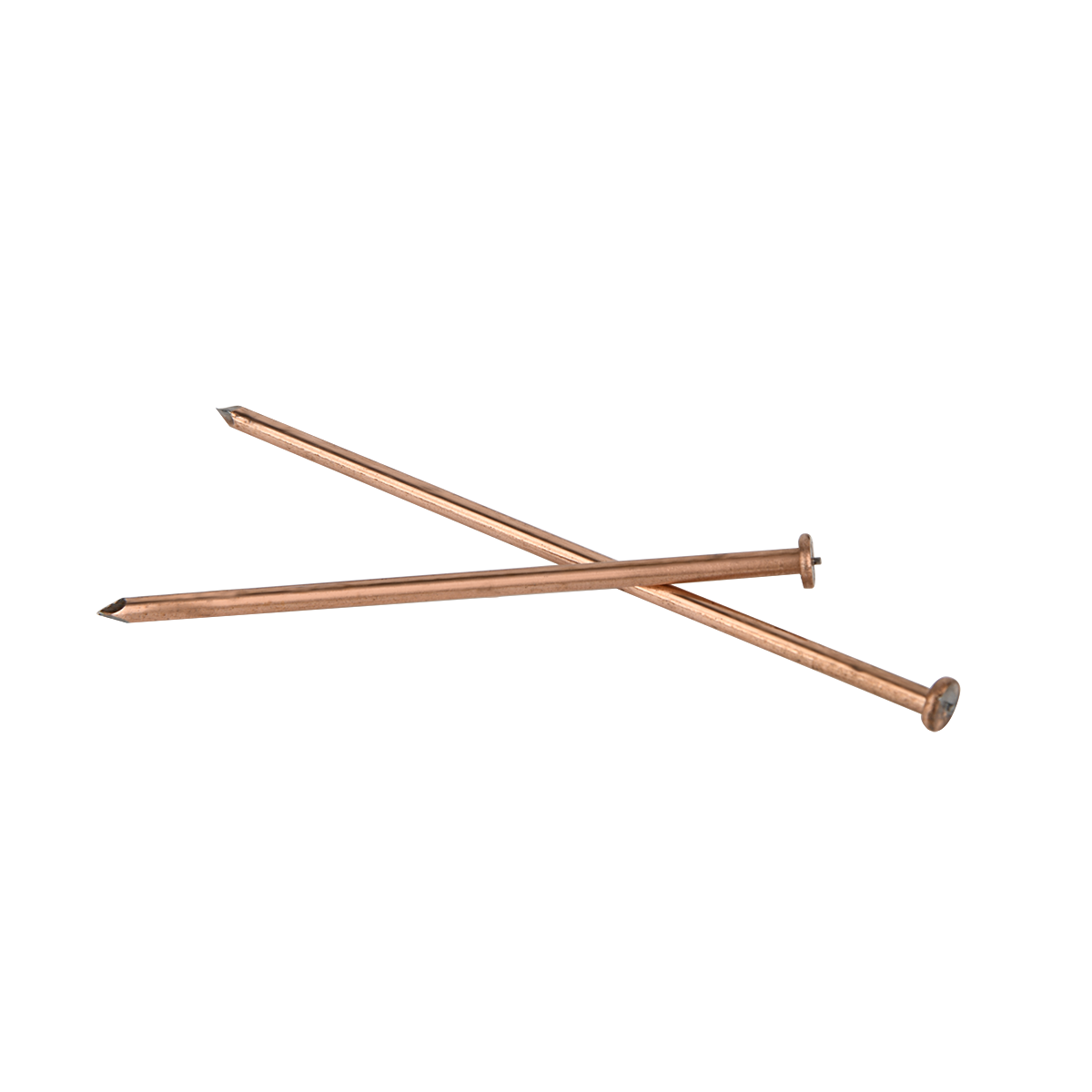

Insulation pins and stud welding form a crucial combination in the field of insulation installation and fastening. Stud welding is a process that offers a reliable and efficient method of attaching insulation pins to various surfaces.

The stud welding process involves creating a strong, metallurgical bond between the stud (in this case, the insulation pin) and the base material. This bond provides excellent mechanical strength and resistance to pull-out forces, ensuring that the insulation pins remain securely in place throughout the lifespan of the insulation system.

Insulation pins used in conjunction with stud welding are typically designed to withstand the high temperatures and forces generated during the welding process. They are often made from materials such as stainless steel or specialized alloys that offer both strength and corrosion resistance.

For example, in the automotive industry, stud welding is employed to attach insulation pins to the vehicle's body panels for sound and heat insulation. The strong bond provided by stud welding ensures that the insulation remains intact even under the vibrations and stresses of driving.

In industrial settings, such as power plants or refineries, stud welding is used to attach insulation pins to large equipment and piping. This helps to maintain the integrity of the insulation and prevent heat loss or gain, improving energy efficiency and process control.

The advantage of stud welding over other fastening methods is its ability to create a consistent and reliable connection. It eliminates the need for drilling holes or using adhesives, which can sometimes fail over time.

Furthermore, stud welding can be automated, allowing for faster and more precise installation of insulation pins on a large scale. This is particularly beneficial in manufacturing environments where production speed and quality are of utmost importance.

In summary, the combination of insulation pins and stud welding provides a robust and long-lasting solution for securing insulation in a wide range of applications, offering improved performance, reliability, and energy savings.