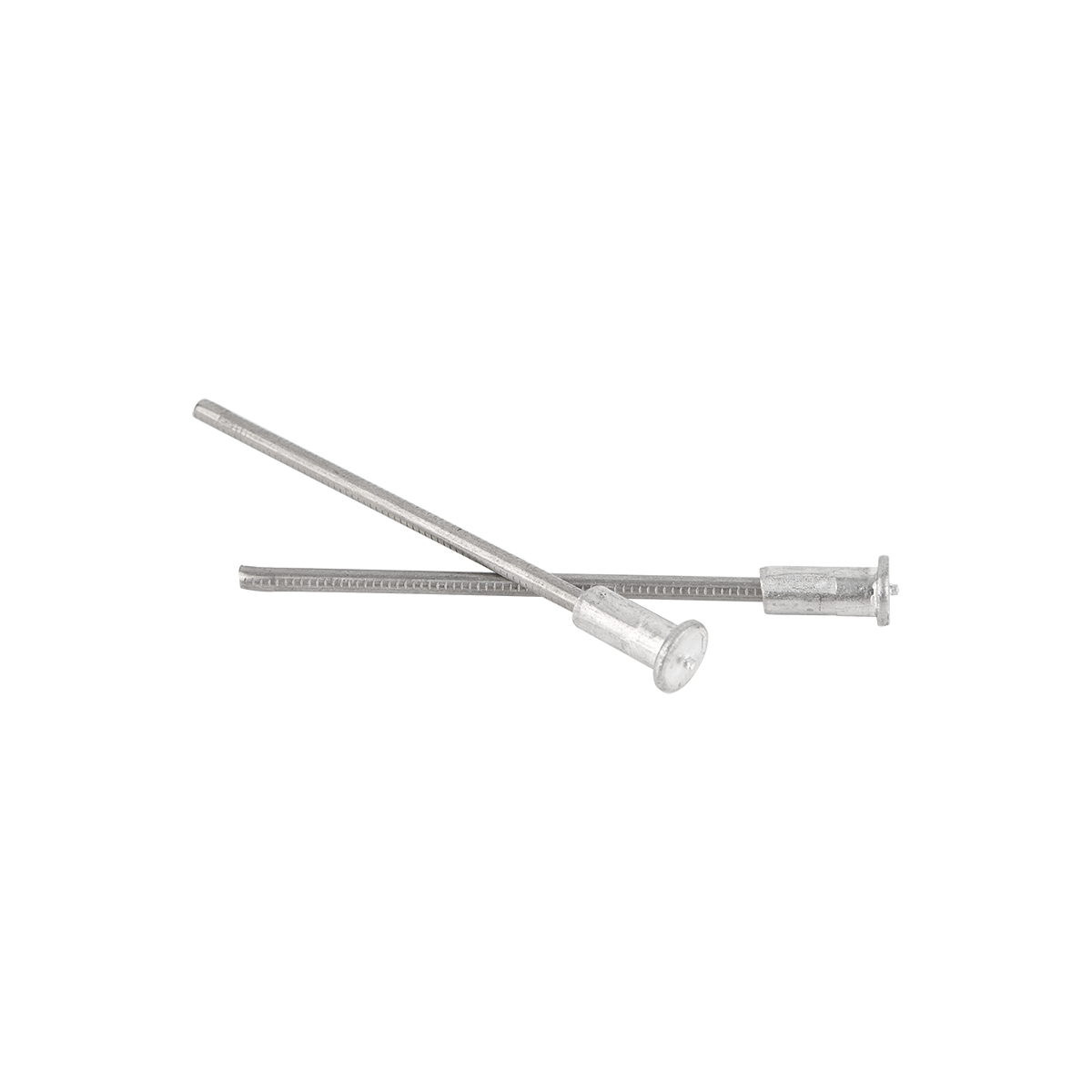

Insulation Pins

Author: admin Date: 2024-08-09 16:25:24 Category: INDUSTRY NEWS

Insulation pins play an important role in the electrical and electronic fields, primarily used to provide electrical connections while ensuring the safety and stability of current transmission. The following is a detailed analysis of Insulation Pins:

1、 Definition and Function

Insulation Pins, Insulated pin is a metal pin with an insulating coating, used to provide a safe current transmission path in electrical connections. They isolate metal pins from the external environment through insulating coatings, preventing current leakage and short circuits, thereby protecting the safety of equipment and users.

2、 Characteristics and advantages

Insulation performance: The core feature of insulated pins is their insulation coating, which can effectively prevent current from flowing through non predetermined paths and improve the safety of electrical connections.

Conductivity: Despite having an insulating coating, the metal part of the insulated pin still maintains good conductivity, ensuring smooth transmission of current.

Corrosion resistance: Insulated pins are usually made of corrosion-resistant materials and can be used for a long time in harsh environments without damage.

Easy to install: The design of insulated pins usually takes into account the convenience of installation, allowing users to easily complete electrical connections.

3、 Application Fields

Insulation Pins are widely used in various situations that require electrical connections, including but not limited to:

Power plugs and sockets: In power plugs and sockets, insulated pins are used to provide a safe path for current transmission and prevent electric shock accidents.

Electronic devices: In electronic devices, insulated pins are used to connect various components on the circuit board to ensure the normal operation of the circuit.

Industrial equipment: In industrial equipment, insulated pins are used to connect various electrical components and sensors to ensure stable operation of the equipment.

Automotive and Aerospace: In the automotive and aerospace industry, insulated pins are used to connect complex electrical systems, ensuring the safety performance of vehicles and aircraft.

4、 Type and Structure

There are various types and structures of insulated pins to meet different application requirements. For example, they may have different diameters, lengths, and insulation coating materials. In addition, some insulation pins also adopt special designs to improve their corrosion resistance, high temperature resistance, or wear resistance.

5、 Related standards and specifications

In order to ensure the quality and safety of insulated pins, various countries and regions have formulated corresponding standards and specifications. For example, the AS/NZS 3112:2000 standard in Australia specifies the requirements and testing methods for insulated pins in plugs and sockets. These standards and specifications provide guidance for the design, manufacturing, and use of insulated pins.

6、 Conclusion

In summary, Insulation Pins, as an important electrical connection component, play an irreplaceable role in the fields of electrical and electronics. They ensure the normal operation of the electrical system by providing a safe current transmission path and protecting the safety of equipment and users. With the continuous advancement of technology and the expansion of application fields, the performance and application scope of insulation pins will also be continuously improved and expanded.