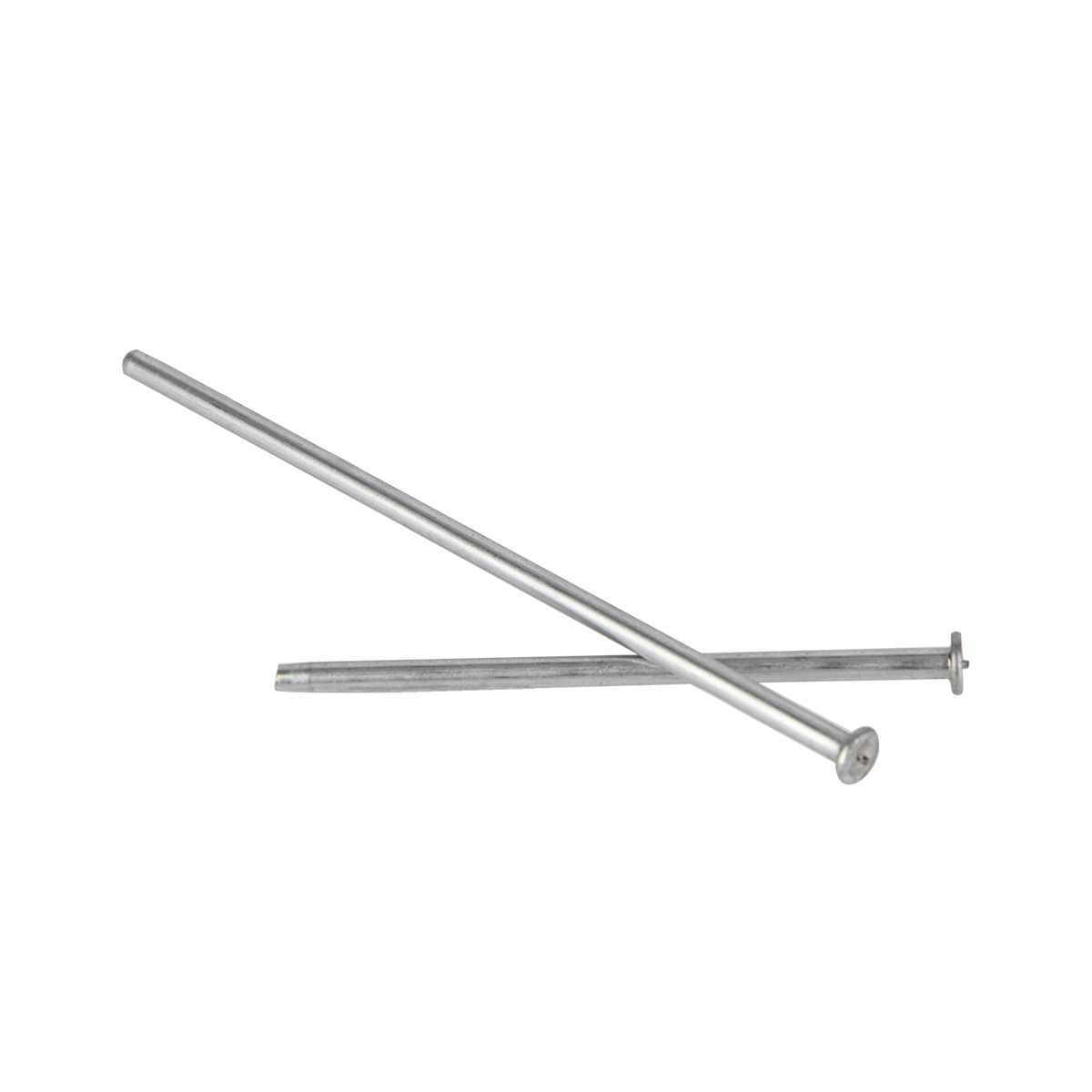

Insulation Weld Pins

Author: admin Date: 2024-08-16 15:59:44 Category: INDUSTRY NEWS

Insulation weld pins are a vital component in the field of insulation and construction. These pins are specifically designed to provide a robust and permanent connection for insulation materials.

The process of using insulation weld pins involves welding them onto the surface where the insulation is to be installed. This welding connection creates a highly secure attachment that is resistant to mechanical stress, vibration, and environmental factors.

Insulation weld pins are typically made from materials that have excellent heat resistance and electrical conductivity, such as certain alloys of steel. This ensures that they can withstand the welding process without losing their structural integrity or performance.

One of the main benefits of insulation weld pins is their ability to create a seamless and uniform insulation layer. When properly installed, they eliminate the potential for gaps or loose areas in the insulation, which can significantly improve the insulation's effectiveness.

For instance, in the aerospace industry, insulation weld pins are used to attach insulation to the aircraft's fuselage. The precise and secure attachment helps to maintain the aircraft's thermal properties during flight and protects sensitive components from extreme temperatures.

In power plants, insulation weld pins are employed to insulate pipes and vessels. The strong weld connection ensures that the insulation remains intact even in high-temperature and high-pressure environments, reducing heat loss and increasing the efficiency of the systems.

The selection of the appropriate insulation weld pins depends on various factors, including the type of surface material, the thickness and type of insulation, and the specific application requirements. Different weld techniques and equipment may also be used to achieve the best results.

In a petrochemical plant, where the insulation needs to withstand corrosive substances and high temperatures, specialized insulation weld pins with corrosion-resistant coatings and suitable weld parameters would be selected to ensure the longevity and effectiveness of the insulation system.

In conclusion, insulation weld pins offer a reliable and durable solution for insulation installations, providing enhanced performance and protection in a wide range of industries and applications.