Manufacturing Process of Insulation Pins

Author: admin Date: 2024-08-16 15:55:58 Category: INDUSTRY NEWS

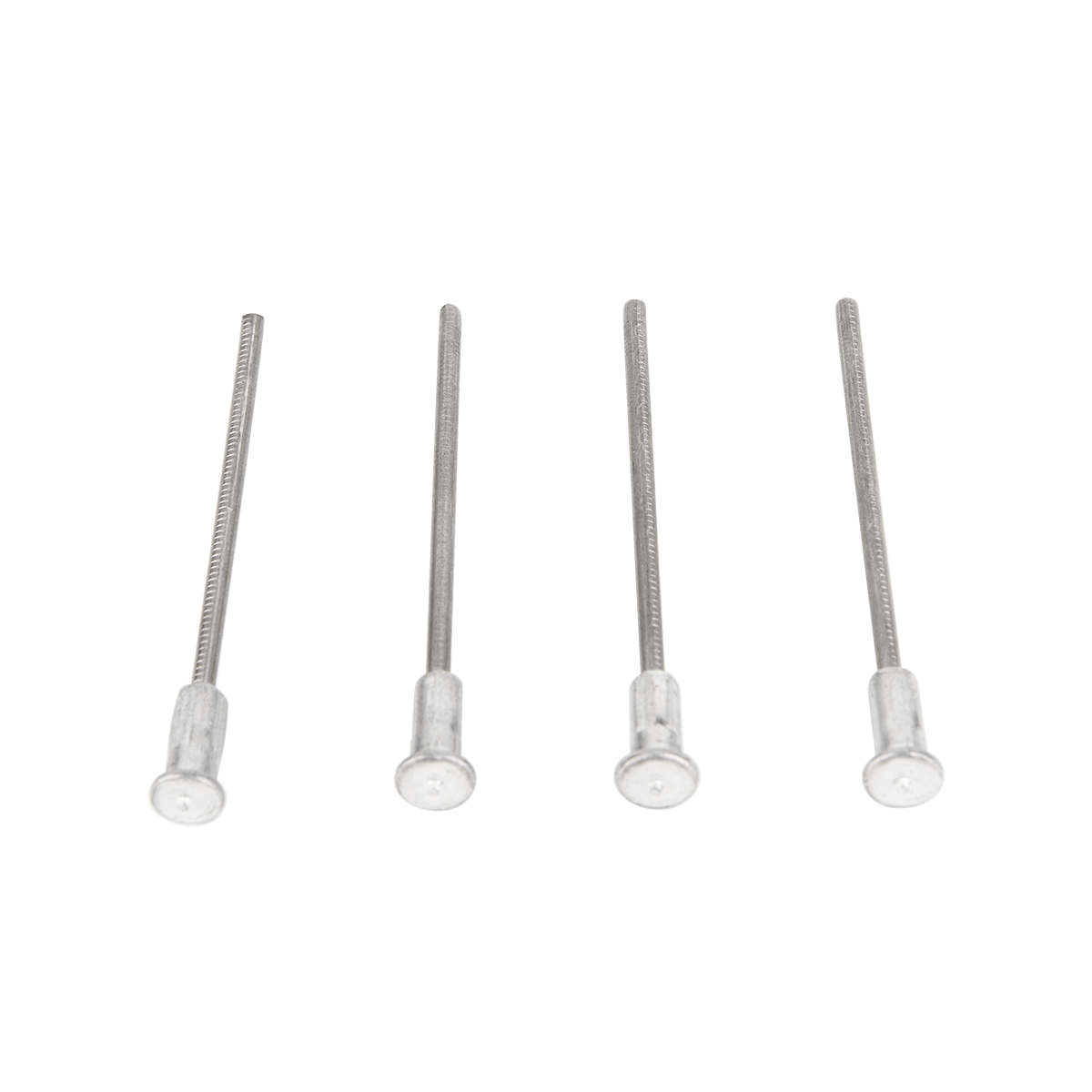

The manufacturing process of insulation pins involves several precise steps to ensure their quality, performance, and reliability.

The first step is the selection of raw materials. Commonly used materials include fiberglass, polymers, or metals depending on the specific requirements of the insulation pins. The quality and properties of these materials greatly influence the final product's strength, insulation capabilities, and durability.

Once the materials are chosen, they undergo molding or shaping processes. This can involve injection molding for polymer-based insulation pins or extrusion for fiberglass or metal pins. The molds or dies are designed to give the pins their desired shape and size, ensuring consistency and accuracy.

In some cases, additional processing steps like machining or cutting may be required to achieve the final dimensions and features of the pins. For example, pins with special heads or threading might undergo these operations.

Surface treatment is an important aspect of the manufacturing process. This can include coating the pins with adhesives for self-adhesive models or applying protective coatings to enhance resistance to corrosion, wear, or environmental factors.

Quality control checks are carried out at various stages of the manufacturing process. This includes inspecting the dimensions, material composition, and mechanical properties of the pins to ensure they meet the specified standards and tolerances.

Testing for insulation performance is also crucial. The pins are subjected to electrical and thermal tests to verify their ability to provide effective insulation.

After passing the quality checks, the insulation pins are packaged and prepared for distribution. Packaging is designed to protect the pins during transportation and storage.

For example, in the production of fiberglass insulation pins, the fiberglass strands are first combined with a resin and then molded into the desired shape. The pins are then coated with an adhesive and inspected for any defects before being packaged.

The manufacturing process of insulation pins requires a combination of advanced technology, skilled labor, and strict quality control measures to produce high-quality products that meet the diverse needs of different applications.