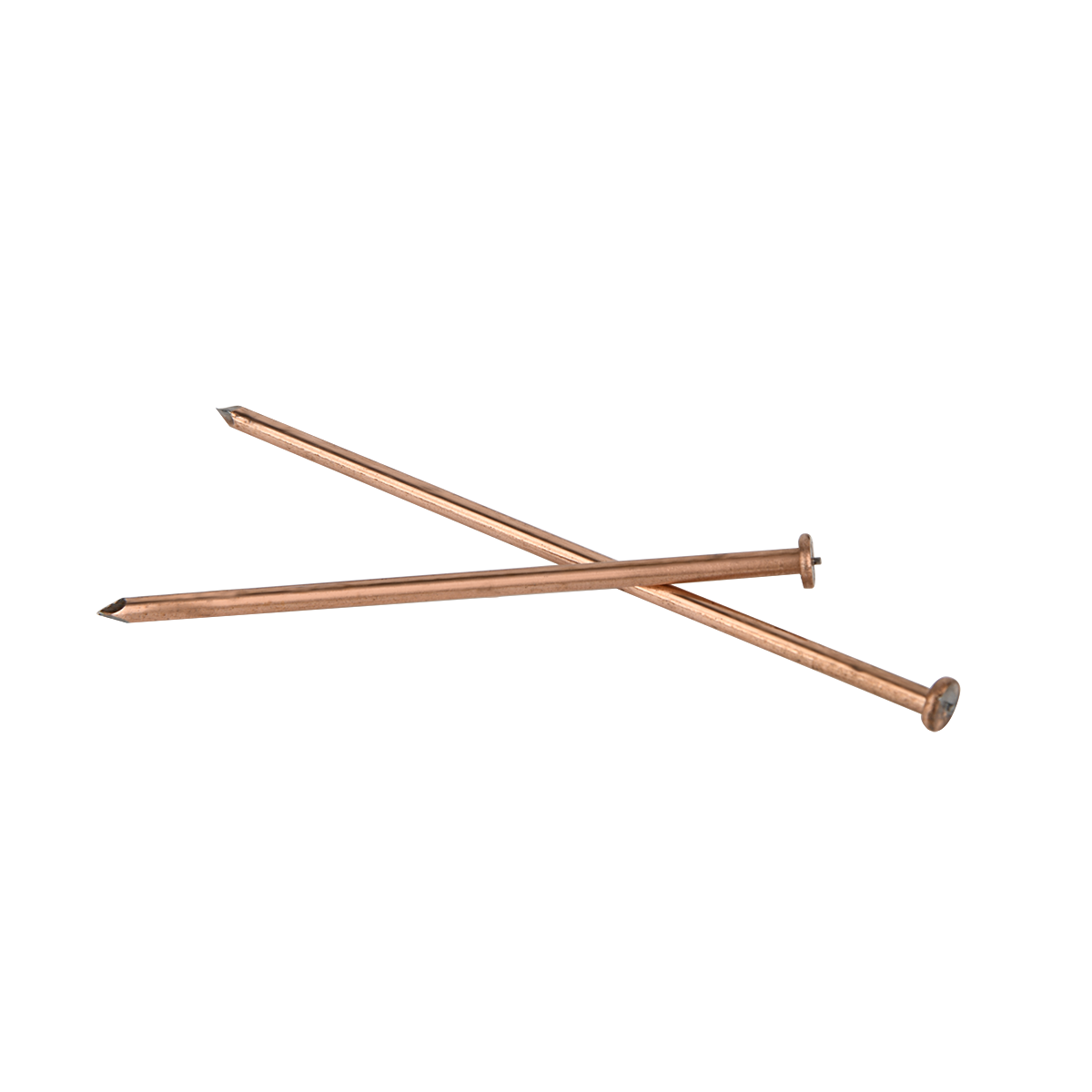

Metal Insulation Pins

Author: admin Date: 2024-08-16 16:02:59 Category: INDUSTRY NEWS

Metal insulation pins are a vital component in insulation systems, offering several key benefits and playing a crucial role in ensuring effective insulation.

These pins are typically made from metals such as stainless steel, aluminum, or galvanized steel, each with its own unique properties that contribute to their performance. Stainless steel, for example, provides excellent corrosion resistance, making it suitable for use in harsh environments or where exposure to moisture is common.

The strength and rigidity of metal insulation pins allow them to securely hold insulation materials in place, preventing sagging or displacement over time. This is particularly important in applications where the insulation needs to withstand mechanical stress or vibration, such as in industrial machinery or transportation equipment.

Metal insulation pins also offer good thermal conductivity properties. While this might seem counterintuitive for insulation, in some cases, it can actually help to distribute heat more evenly and prevent hotspots from developing within the insulation layer.

For instance, in automotive engine compartments, metal insulation pins can be used to attach heat shields and insulation materials. The pins' ability to conduct heat to some extent helps to manage the temperature distribution and protect sensitive components.

In construction, metal insulation pins are commonly used in the insulation of walls, roofs, and floors. Their durability ensures that the insulation remains firmly in position for the long term, contributing to the energy efficiency and structural integrity of the building.

Another advantage of metal insulation pins is their recyclability. As sustainability becomes an increasingly important consideration, the use of recyclable materials like metals in insulation systems is seen as a positive attribute.

However, it's important to note that the choice of metal for the insulation pins should be based on the specific requirements of the application. Factors such as the type of insulation material, the environment, and the expected load and stress need to be taken into account.

For example, in a marine environment where saltwater corrosion is a concern, galvanized steel or stainless steel insulation pins would be a better choice than aluminum.

In summary, metal insulation pins provide a reliable and durable solution for holding insulation materials in place, contributing to efficient insulation and the overall performance of various systems and structures.