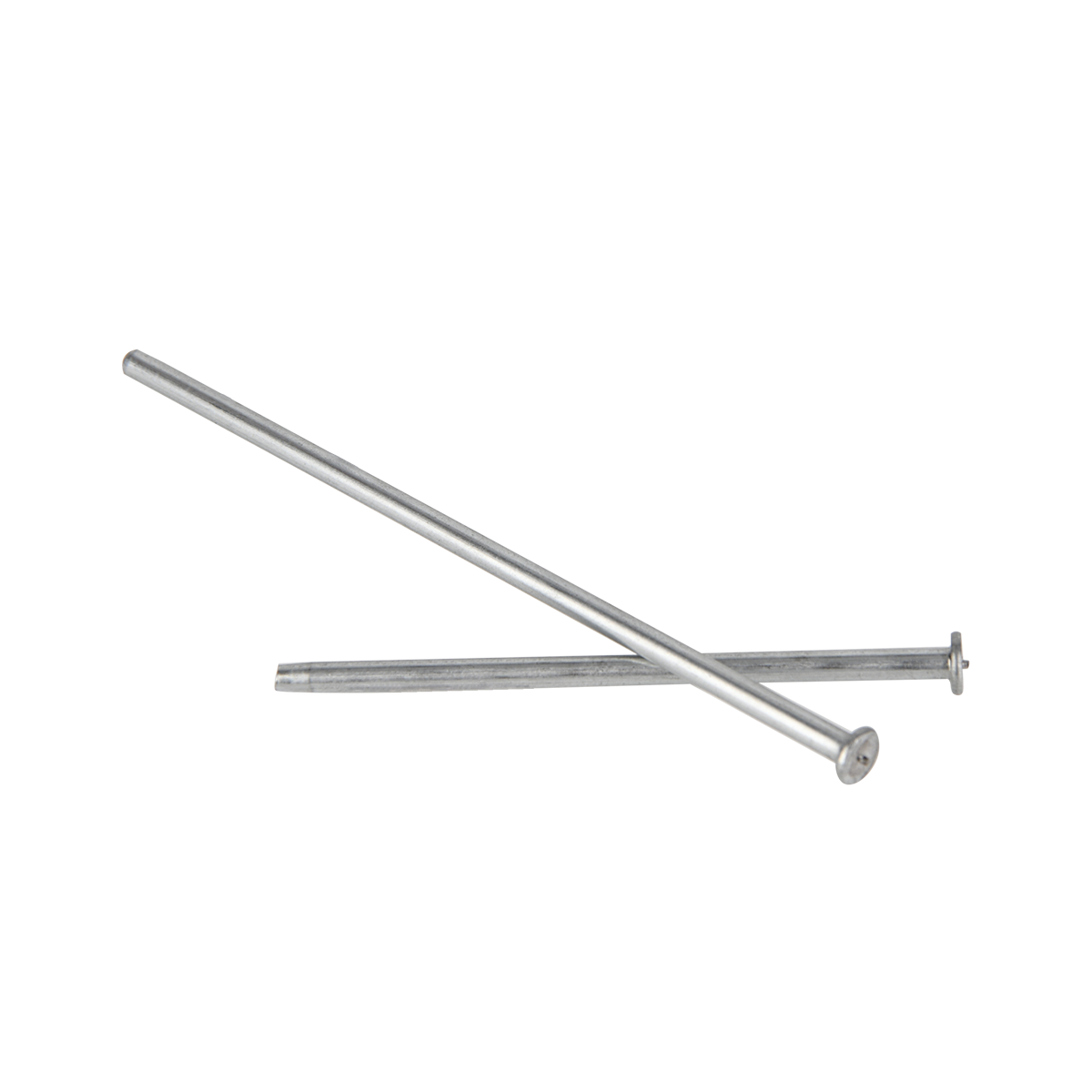

Odd insulation pins on boiler tubes

Author: admin Date: 2024-09-04 16:35:22 Category: INDUSTRY NEWS

Insulation pins on boiler tubes play a crucial role in ensuring the efficient operation and safety of boilers. However, when there are odd insulation pins, it can pose several challenges and considerations.

Odd insulation pins on boiler tubes may occur due to various reasons. It could be a result of improper installation, damage during operation, or wear and tear over time. These pins can disrupt the uniformity of the insulation layer and potentially affect the heat transfer characteristics of the boiler tubes.

One of the main concerns with odd insulation pins is the potential for heat loss. If the insulation is not evenly distributed around the tubes, heat can escape more easily, reducing the efficiency of the boiler. This can lead to increased energy consumption and higher operating costs.

In addition to heat loss, odd insulation pins can also create safety hazards. They may cause uneven stress on the tubes, increasing the risk of tube failure or leakage. This can be particularly dangerous in high-pressure boiler systems where a failure could result in serious accidents.

To address the issue of odd insulation pins on boiler tubes, regular inspection and maintenance are essential. Inspectors should carefully examine the insulation layer to identify any pins that are out of place or damaged. These pins can then be replaced or adjusted to ensure a proper fit and uniform insulation.

During installation, it is important to follow proper procedures and use high-quality insulation pins. This will help to minimize the occurrence of odd pins and ensure a reliable insulation system. Manufacturers should also provide clear instructions and guidelines for installation to ensure that installers are aware of the correct methods and best practices.

In some cases, it may be necessary to retrofit the insulation system to address odd pins. This could involve adding additional insulation or using specialized fasteners to secure the insulation in place. Retrofit projects should be carefully planned and executed to ensure that they do not disrupt the operation of the boiler or compromise its safety.

For example, in a power plant, odd insulation pins on boiler tubes can lead to decreased efficiency and increased maintenance costs. By conducting regular inspections and addressing any issues promptly, plant operators can ensure the reliable operation of the boilers and reduce the risk of downtime and costly repairs.

In conclusion, odd insulation pins on boiler tubes can have significant implications for the performance and safety of boilers. Through regular inspection, proper installation, and timely maintenance, these issues can be addressed to ensure the efficient and safe operation of boiler systems.