Range of Insulation Pins!

Author: admin Date: 2024-08-16 15:58:41 Category: INDUSTRY NEWS

The range of insulation pins is a diverse and essential aspect of the insulation industry. These pins come in a variety of types, designs, and materials, each tailored to specific insulation applications and requirements.

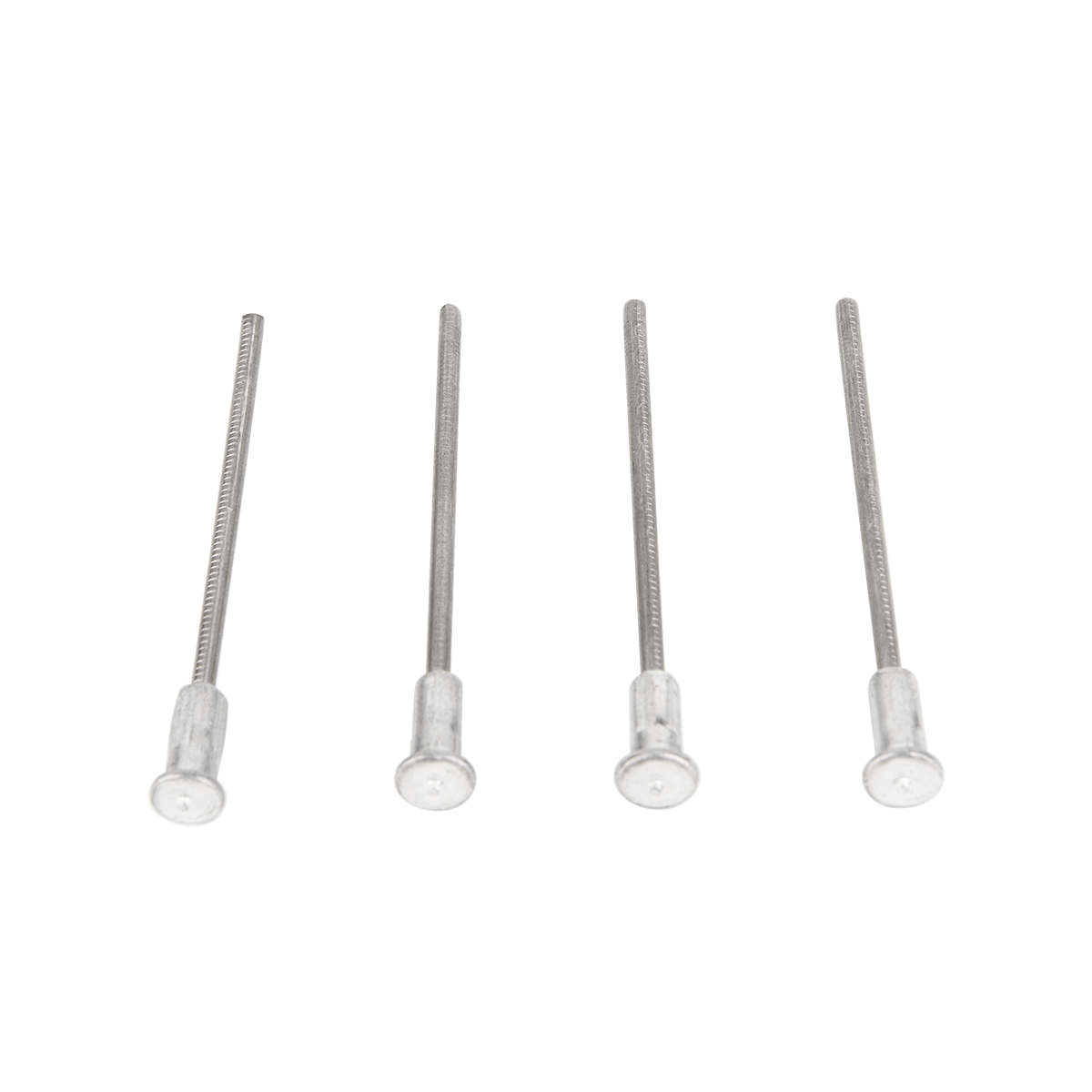

Insulation pins can be classified based on their size, shape, and the type of insulation material they are intended to secure. Some are short and thin, suitable for lightweight insulation materials, while others are longer and thicker to handle more substantial and dense insulation.

The materials used to manufacture insulation pins also vary. Common materials include stainless steel, which offers excellent corrosion resistance, and galvanized steel for added durability. There are also pins made from plastic or composite materials, which may be preferred in certain environments where electrical conductivity or chemical resistance is a concern.

For example, in a marine environment where saltwater exposure is a factor, stainless steel insulation pins would be the preferred choice due to their ability to withstand corrosion. In an area with high electromagnetic interference, non-metallic pins might be selected to avoid conductivity issues.

The range of insulation pins also encompasses pins with different head shapes and designs. Some have flat heads for a flush finish, while others have pointed or domed heads for better penetration and grip.

In addition to their physical characteristics, insulation pins can be designed for specific installation methods. Some are suitable for manual insertion, while others are compatible with power tools for faster and more efficient installation on large-scale projects.

Whether it's for insulating walls, roofs, pipes, or equipment, the wide range of insulation pins ensures that there is a suitable option for every insulation job. This diversity allows for precise and effective insulation solutions, contributing to energy savings, improved comfort, and protection against environmental factors.