Stuck Up Insulation Pins selection

Author: admin Date: 2024-08-09 16:30:09 Category: INDUSTRY NEWS

When choosing Stuck Up Insulation Pins, multiple factors need to be considered comprehensively to ensure the selection of high-quality products that meet your needs.

Firstly, it is crucial to pay attention to the quality of the adhesive. High quality adhesives should have excellent bonding strength, be able to firmly adhere to different substrate surfaces (such as concrete, wood, metal, etc.), and remain stable under environmental conditions such as temperature changes and humidity fluctuations. For example, in a basement environment with high humidity, adhesives need to have good water resistance to prevent bond failure.

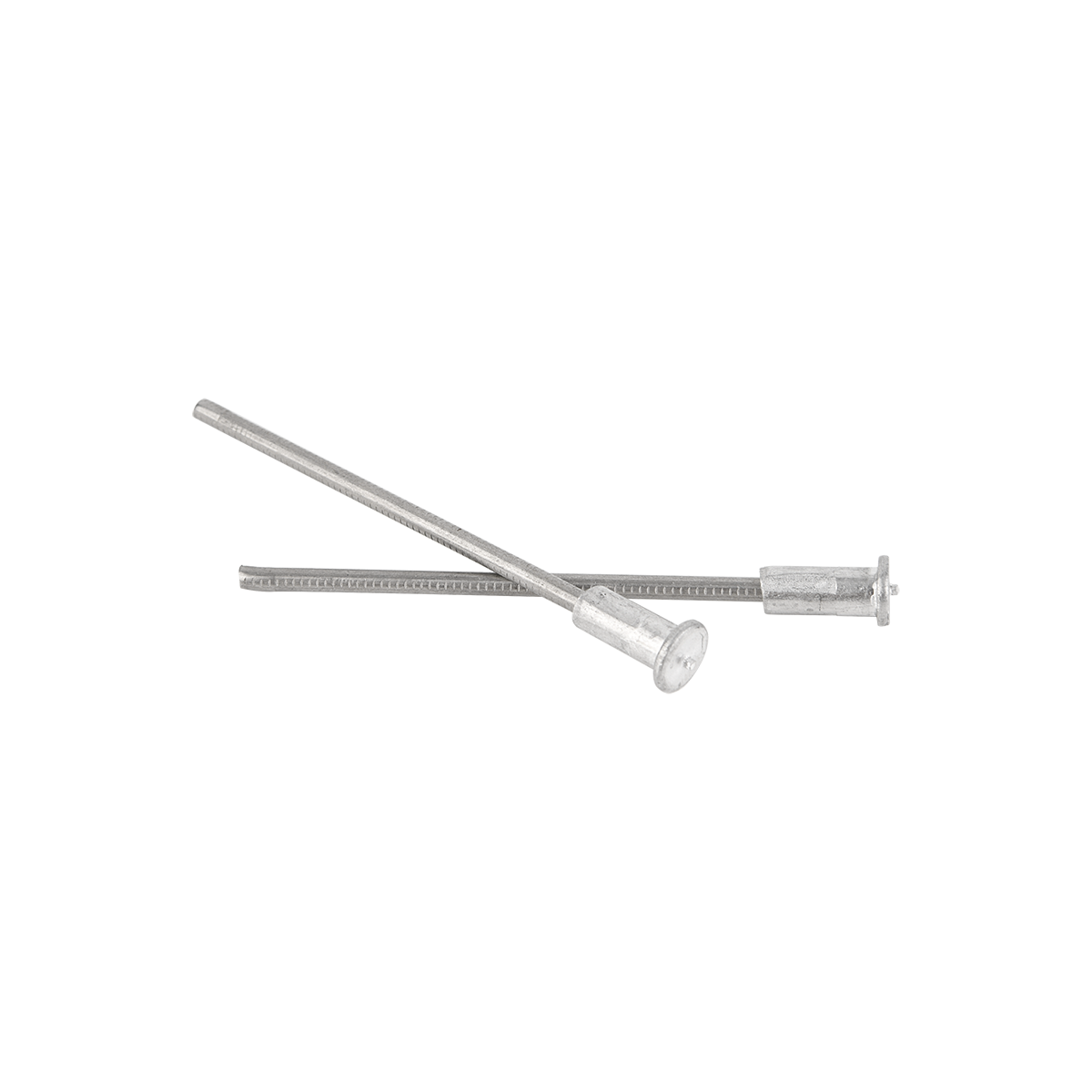

Secondly, pay attention to the material of the insulation nails. Common materials include stainless steel and galvanized steel. Stainless steel has better corrosion resistance and is suitable for applications exposed to harsh environments for a long time; Galvanized steel performs well in general environments and has relatively low costs. Choose appropriate materials based on specific usage scenarios and budget. For example, in seaside buildings, due to the high salt content in the air, stainless steel Stuck Up Insulation Pins are more resistant to corrosion.

Furthermore, consider the size and shape of the insulation nails. The size should match the thickness and weight of the insulation material to provide sufficient support. In terms of shape, some insulation nails have larger heads, which can provide better pressure distribution and prevent local sinking of insulation materials. At the same time, it is necessary to check the surface treatment of the insulation nails. A smooth and burr free surface can help reduce damage to the insulation material during installation.

In addition, the reputation of the brand and manufacturer is also an important reference when making a purchase. Famous brands usually have more assurance in product quality control, after-sales service, and technical support. The reliability of a brand can be evaluated by examining user reviews, industry recommendations, and product certifications.

Finally, price is also a factor to consider, but quality should not be overlooked in pursuit of low prices alone. Within a reasonable budget range, choose products with high cost-effectiveness to ensure that they can meet engineering needs while controlling costs.