The Development of New Materials for Insulation Pins

Author: admin Date: 2024-08-16 15:55:22 Category: INDUSTRY NEWS

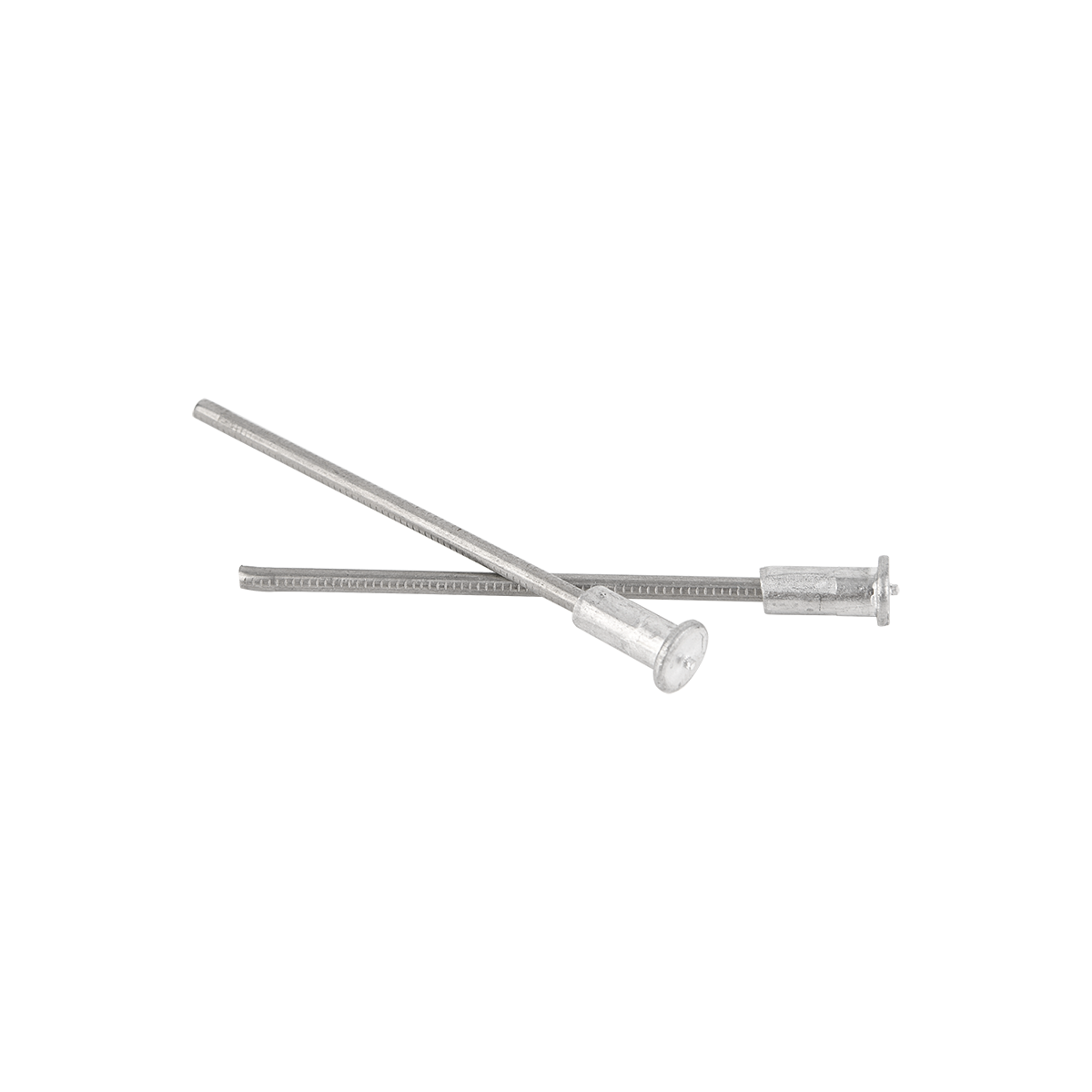

The field of insulation pins is constantly evolving, with significant advancements in the materials used. New materials are being developed to meet the increasing demands for better insulation performance, durability, and environmental friendliness.

One notable development is the use of advanced composites in insulation pin manufacturing. These composites combine the properties of different materials, such as fiberglass and polymers, to create a material that offers superior strength, insulation capabilities, and resistance to environmental factors. For instance, a composite material might have enhanced resistance to high temperatures and chemicals, making it suitable for use in harsh industrial environments.

Nanomaterials are also making their way into the insulation pin industry. Nanotechnology enables the creation of materials with improved thermal conductivity and insulation properties at a microscopic level. This can lead to more efficient insulation and reduced heat transfer.

Sustainable and eco-friendly materials are gaining importance. Biodegradable polymers or recycled materials are being explored to reduce the environmental impact of insulation pins. These materials not only offer comparable performance but also contribute to a more sustainable future.

Another area of development is the creation of self-healing materials. These materials have the ability to repair minor damage or cracks over time, increasing the lifespan and reliability of the insulation pins.

For example, in certain applications where insulation pins are exposed to frequent mechanical stress, a self-healing material could automatically mend small fractures, maintaining the integrity of the insulation system.

The development of new materials also focuses on improving the fire resistance of insulation pins. Materials that can withstand high temperatures and prevent the spread of fire are crucial for safety in various settings, such as buildings and industrial facilities.

As research and development continue, we can expect to see even more innovative materials that will revolutionize the performance and application of insulation pins in the future.