The Main Materials of Insulation Pins

Author: admin Date: 2024-08-16 15:57:13 Category: INDUSTRY NEWS

Insulation pins are typically made from a variety of materials, each with its unique properties and suitability for different applications. One of the common materials is fiberglass. Fiberglass insulation pins offer excellent electrical insulation properties and are highly resistant to heat. They are lightweight and can withstand a wide range of temperatures without significant degradation. This makes them ideal for use in applications where both thermal and electrical insulation are crucial, such as in electrical equipment or industrial furnaces.

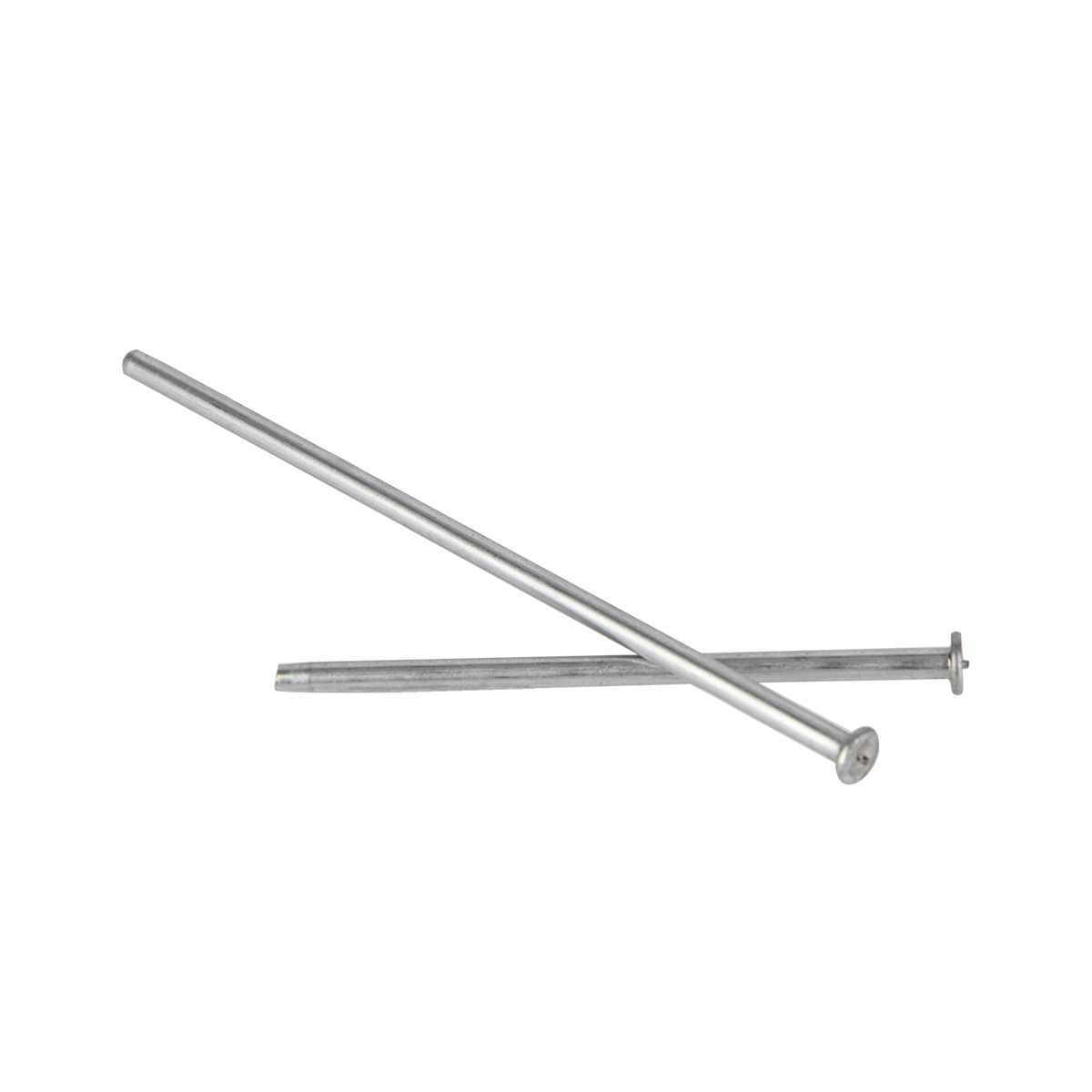

Stainless steel is another frequently used material for insulation pins. It provides superior strength and durability, making it suitable for heavy-duty applications and environments where resistance to corrosion is essential. Stainless steel insulation pins can withstand exposure to moisture, chemicals, and harsh outdoor conditions, making them a preferred choice in many industrial and marine settings.

Nylon is a popular material due to its combination of good insulation properties and affordability. Nylon insulation pins are lightweight, have decent mechanical strength, and are resistant to abrasion and certain chemicals. They are often used in less demanding applications or where cost is a significant factor.

Polypropylene is also commonly used. It offers good insulation capabilities and is resistant to moisture and many common chemicals. Polypropylene insulation pins are often chosen for applications where moisture resistance is important, such as in damp basements or humid industrial areas.

Some insulation pins are made from composite materials that combine the benefits of different substances. For instance, a composite of fiberglass and a polymer resin can offer enhanced mechanical strength and improved insulation performance. These composites are often engineered to meet specific application requirements and provide a balance of properties.

For example, in aerospace applications, where weight and performance are critical, specialized composite insulation pins might be used to insulate sensitive components and structures.

The choice of material for insulation pins depends on factors such as the operating environment, the type and thickness of the insulation material, the required mechanical strength, and the budget. Understanding the properties and limitations of each material is essential to select the most appropriate insulation pins for a given application.