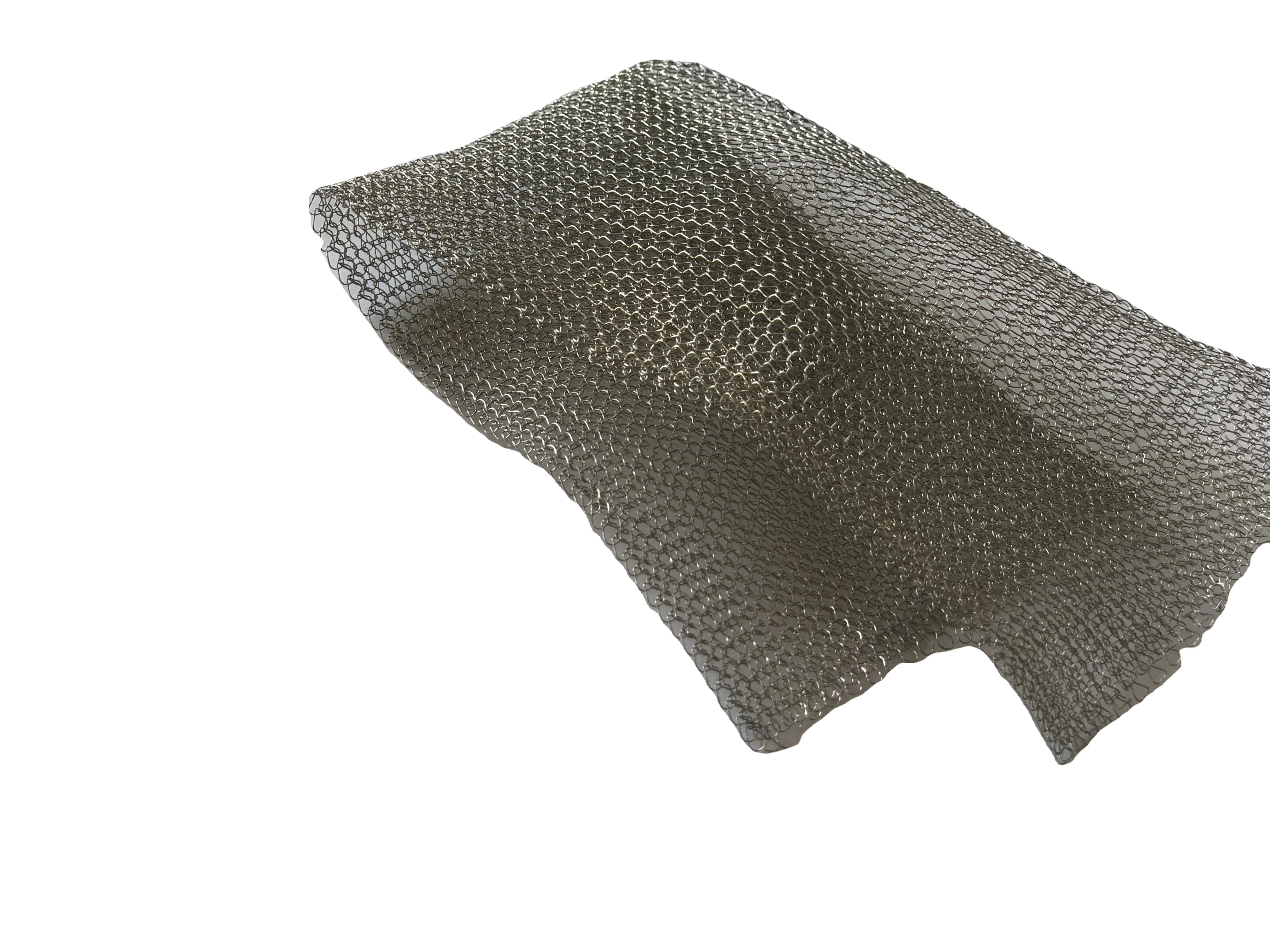

2024 Knitted Wire Mesh

The year 2024 brings with it new advancements and opportunities in the field of knitted wire mesh. T

Contact

Product Detail

The year 2024 brings with it new advancements and opportunities in the field of knitted wire mesh. This versatile material is set to play an even more significant role in a wide range of industries and applications.

In the manufacturing sector, 2024 sees improvements in the knitting technology used to produce wire mesh. This leads to more precise and consistent mesh structures, with tighter tolerances and enhanced mechanical properties. This is particularly important in applications where the mesh needs to withstand high stress and fatigue, such as in automotive components and aerospace structures.

The development of new alloys and materials for knitted wire mesh in 2024 opens up possibilities for greater strength, corrosion resistance, and conductivity. For example, in the electronics industry, advanced knitted wire mesh with enhanced conductivity can be used in heat sinks and electromagnetic shielding to improve the performance and reliability of devices.

In the field of filtration, 2024 brings innovations in the design and functionality of knitted wire mesh filters. These filters are becoming more efficient at trapping smaller particles while maintaining low pressure drops, improving the overall filtration process. This is crucial in industries such as water treatment and air purification, where clean and pure substances are of utmost importance.

Architectural and design applications of knitted wire mesh are also evolving in 2024. New aesthetically pleasing patterns and finishes are available, allowing for more creative and visually striking designs in buildings and interiors. A modern office building might feature a façade made of intricately designed knitted wire mesh that not only provides shade and privacy but also adds a unique architectural statement.

The medical industry is benefiting from knitted wire mesh in 2024 as well. New developments in mesh-based implants and prosthetics offer better biocompatibility and functionality, improving patient outcomes. For instance, knitted wire mesh scaffolds for tissue regeneration are becoming more advanced, promoting faster and more effective healing.

Furthermore, the use of sustainable and recyclable materials in the production of knitted wire mesh is gaining momentum in 2024, in line with the growing focus on environmental consciousness. This helps reduce the environmental impact of manufacturing processes and promotes a more circular economy.

In summary, 2024 marks a year of exciting developments and expanded applications for knitted wire mesh, offering innovative solutions across multiple industries and contributing to technological progress and improved quality of life.